The main direction of the Department (years of existence of the Department: 1930-2019) and created by its specialists scientific and engineering center «Compressor, vacuum, refrigeration and systems of gas transport and processing» are research and development in the field of compressor technology.

The history of the scientific and technical school of our center dates back to 1930!

August 21, 1930 at the Leningrad Polytechnic Institute by the name of M. I. Kalinin the Department of compressor engineering was created. The world’s first specialized Department of compressors and compressor technology.

The first chair was an outstanding scientist of power engineering Konstantin Ivanovich Strakhovich!

During the years of existence of Department CVRT from 1930 to 2019, 145 candidate’s and 16 doctoral thesis were written and defended at the Department.

Konstantin Pavlovich Seleznev — founder of the scientific school of compressor engineering in LPI-SPbPU. . from 1960 to 1989 he was the head of the LPI compressor engineering Department – the country compressor engineering leading scientific center. In 1973 – 1983 he was the rector of the Institute. After 1989 he was a Professor — scientific director of research groups related to the topic of centrifugal compressors of high and ultrahigh pressure.

Chairman of the petroleum Ministry NTS and USSR chemical industry, Chairman of the compressor engineering section.

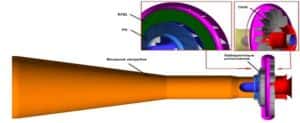

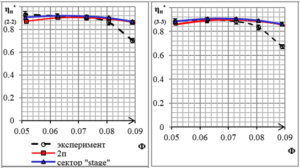

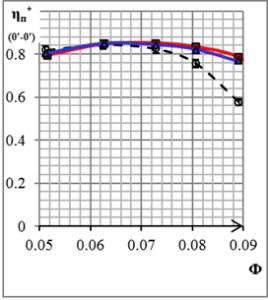

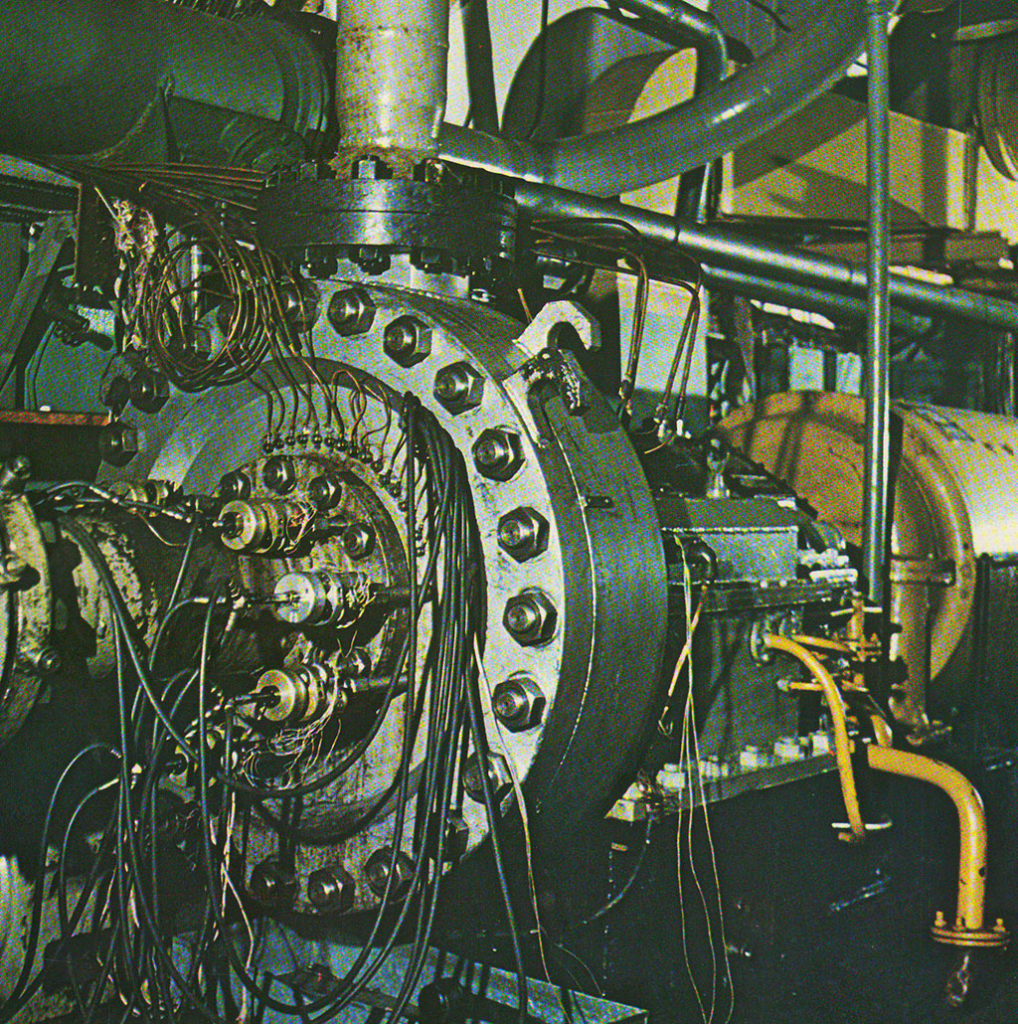

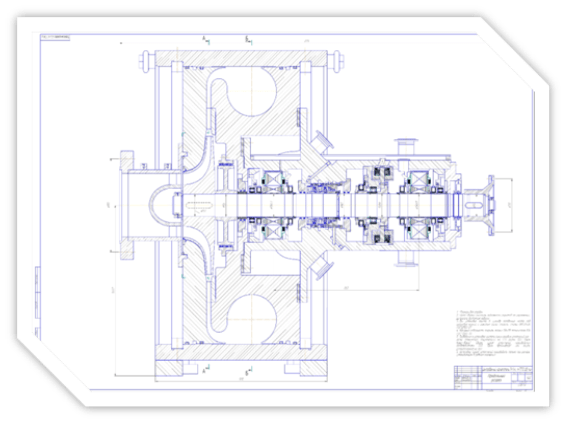

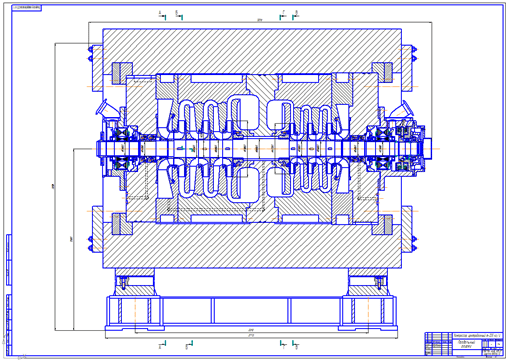

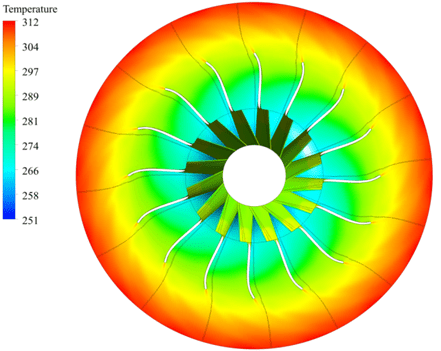

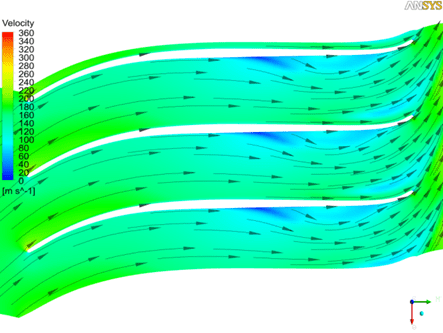

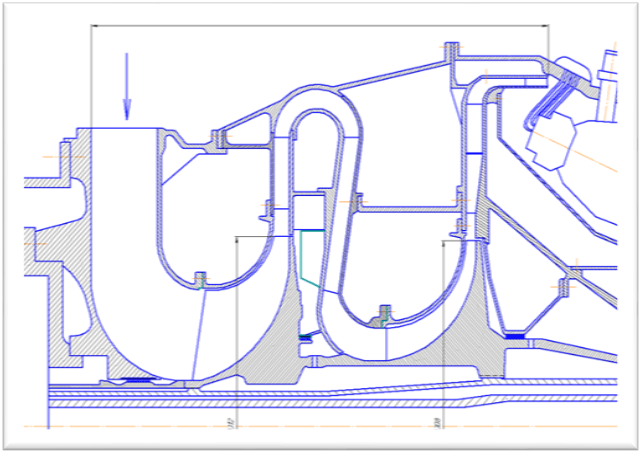

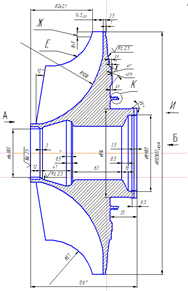

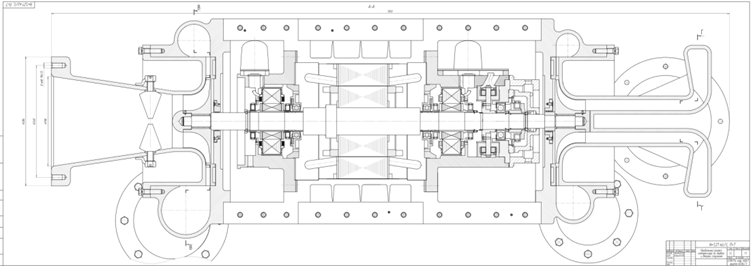

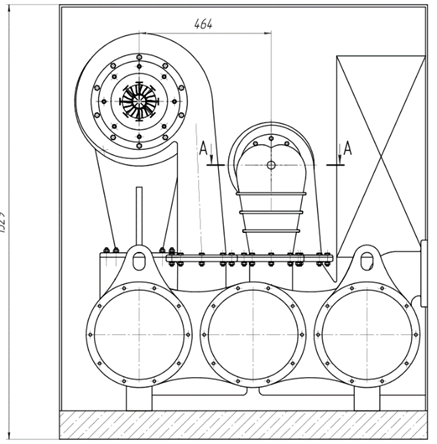

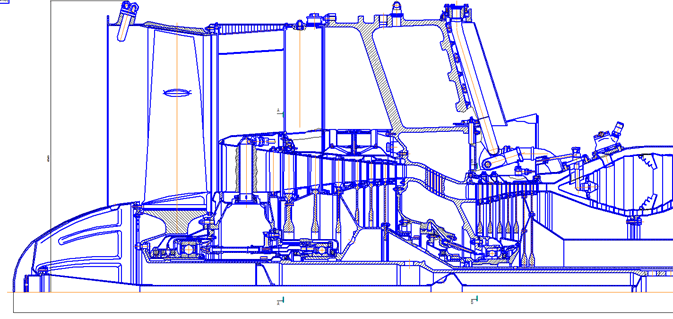

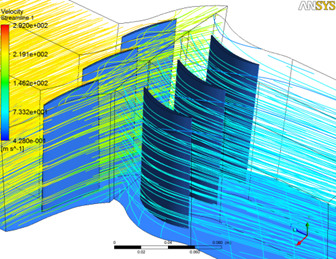

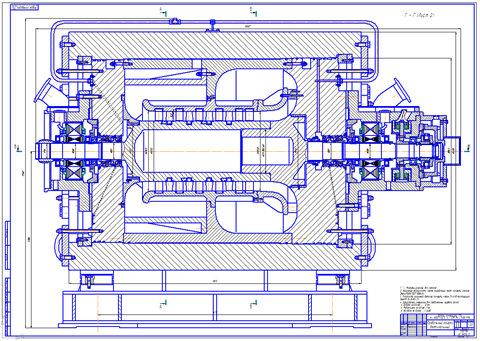

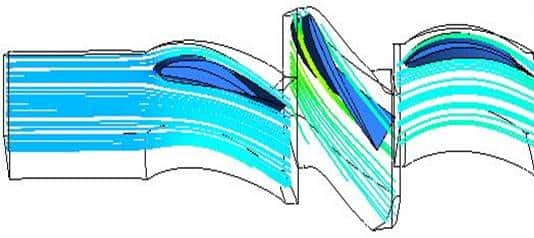

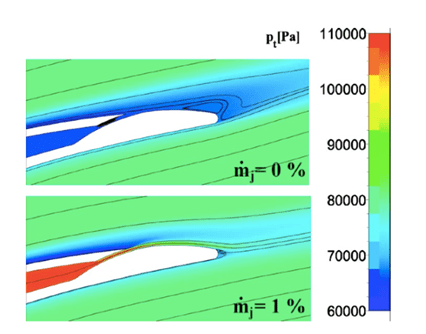

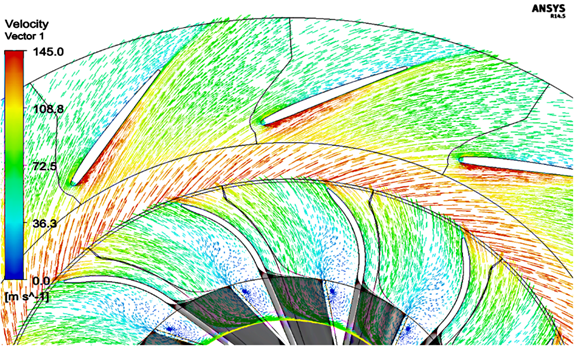

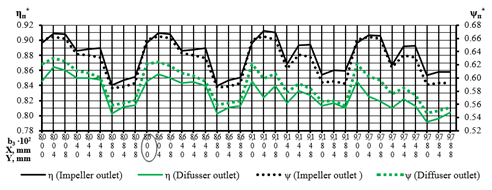

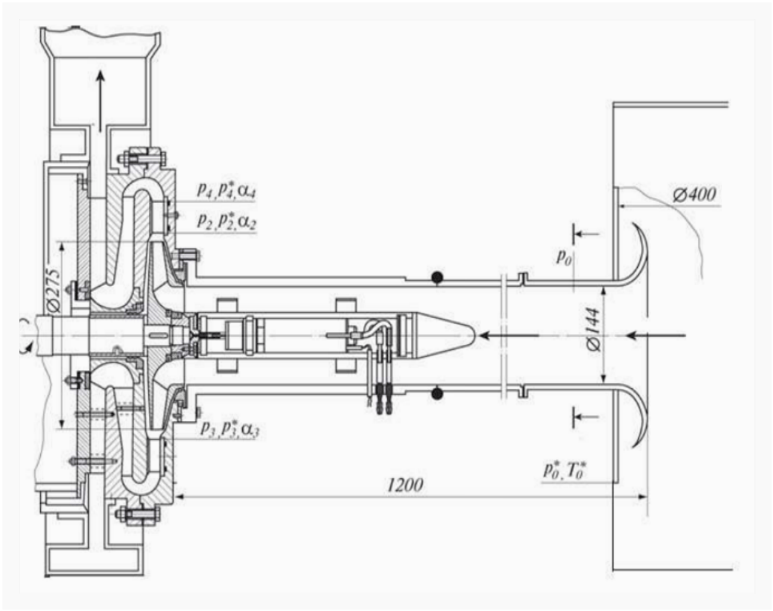

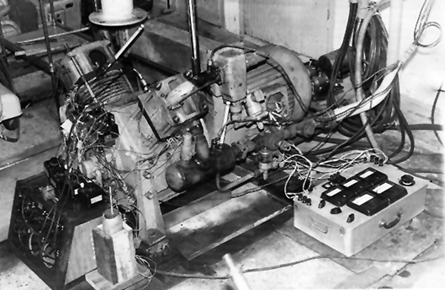

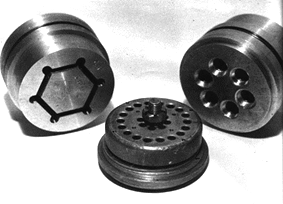

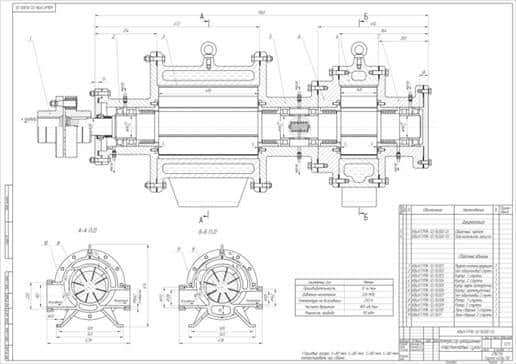

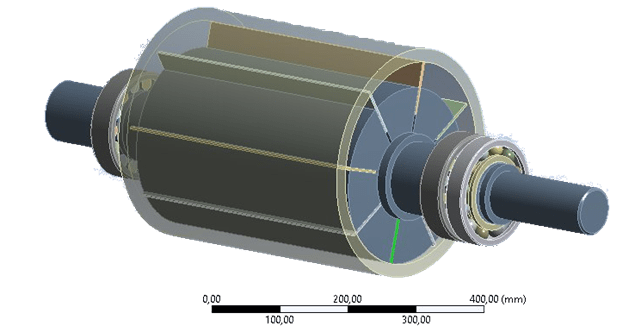

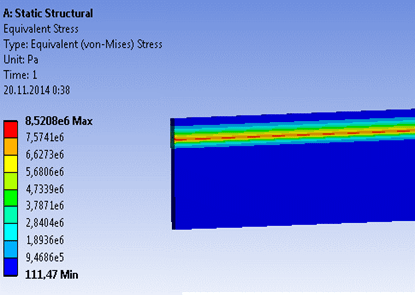

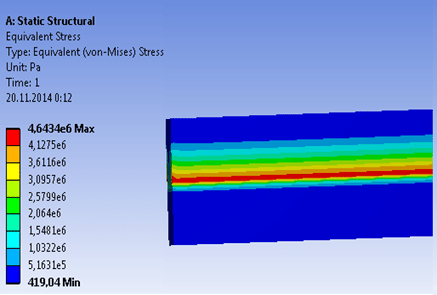

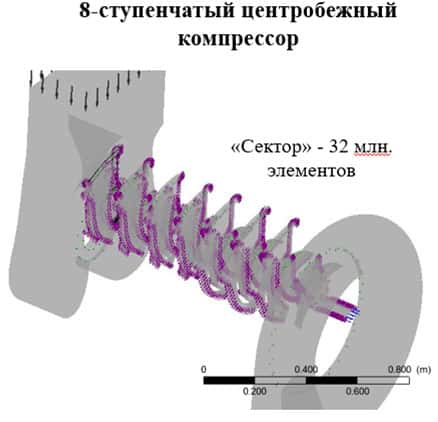

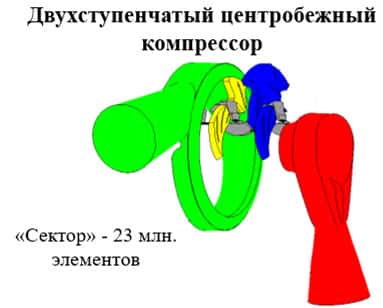

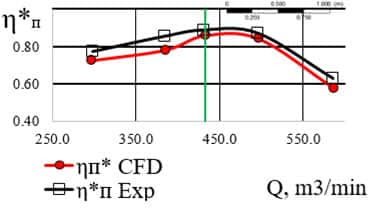

We have a significant experimental and verification base of CFD modeling results

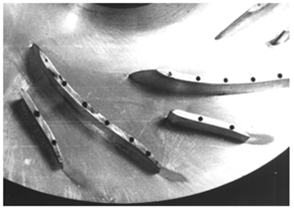

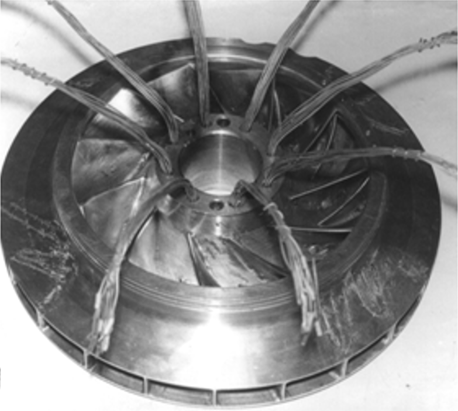

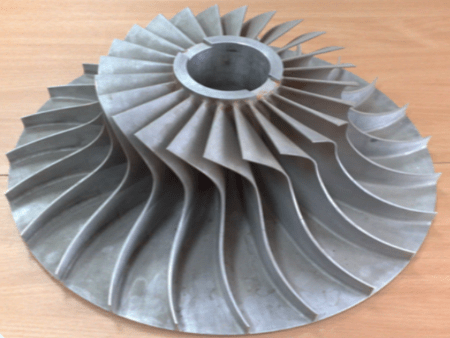

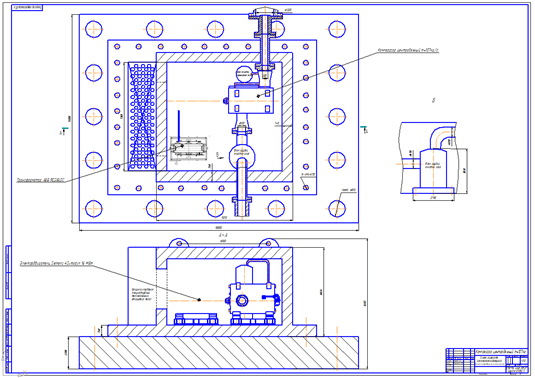

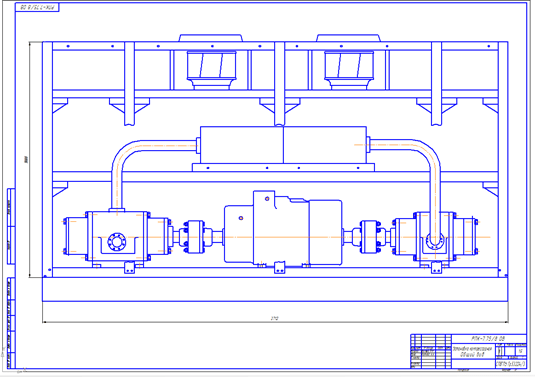

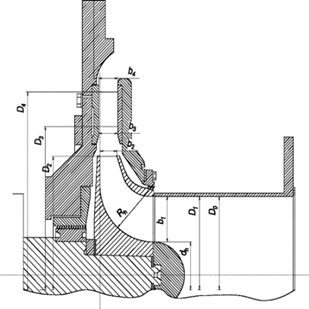

Model stages of the Department

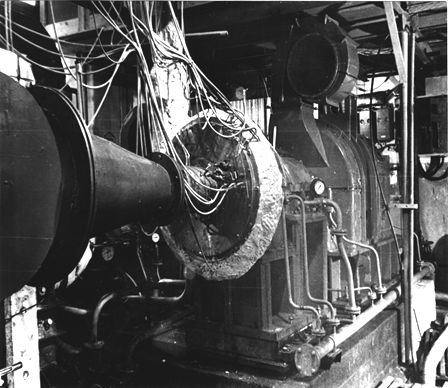

Experimental stands of the CVRE Department

Experimental studies of compressor models on special stands are necessary for the development of the design problems theory and solution.

The scale of the research results implementation.

For example, only for the gas industry of OAO «Gazprom» and other countries more than 50 implemented compressor projects in the amount of more than 330 parts with an installed capacity of about 5 million kW – this is about 10% of all centrifugal compressors for compressing natural gas of OAO»Gazprom».

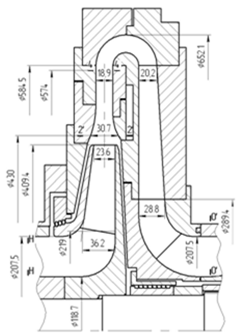

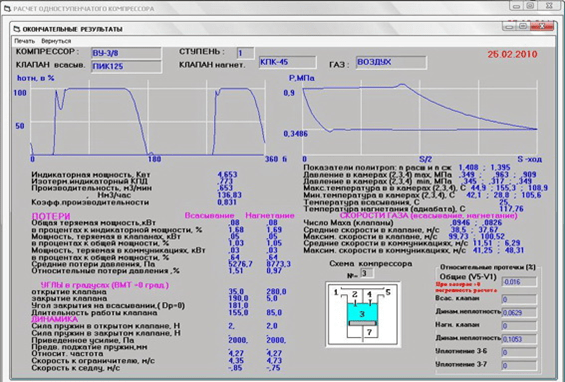

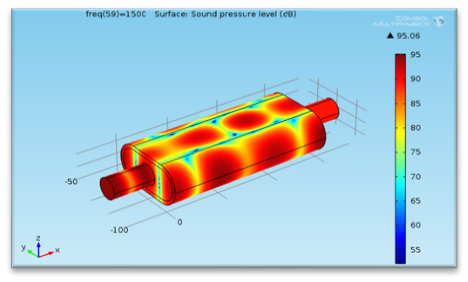

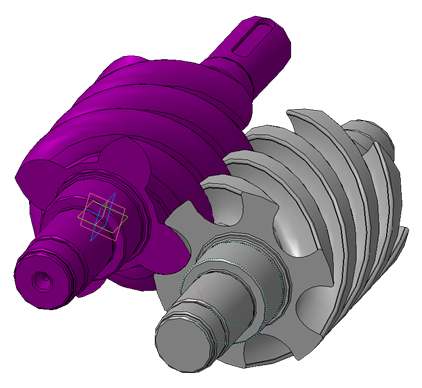

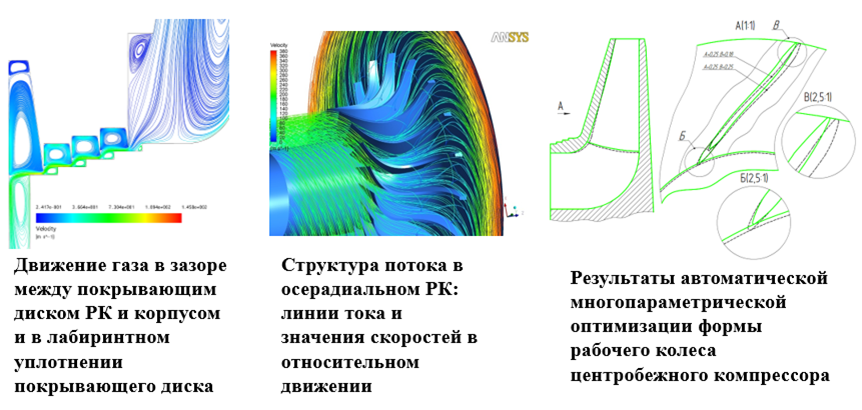

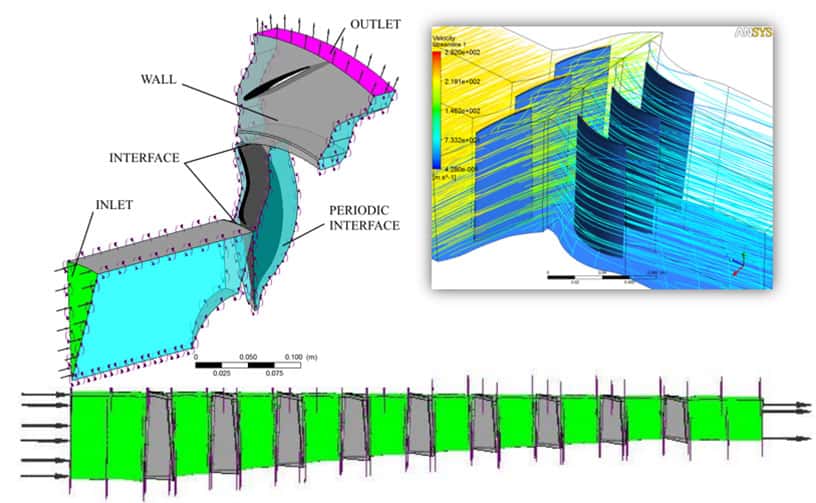

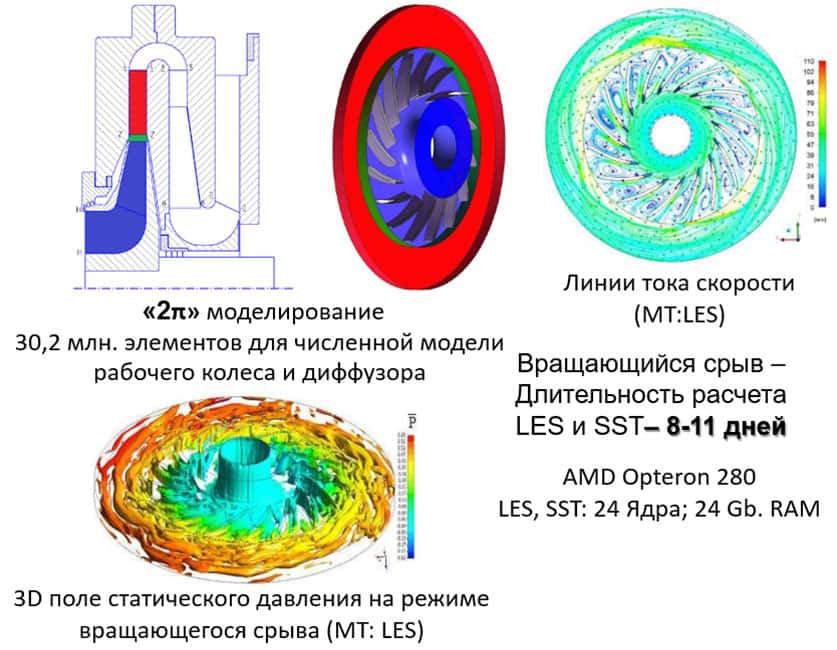

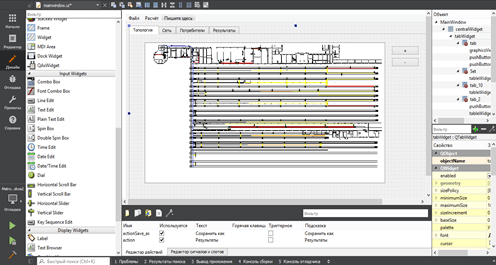

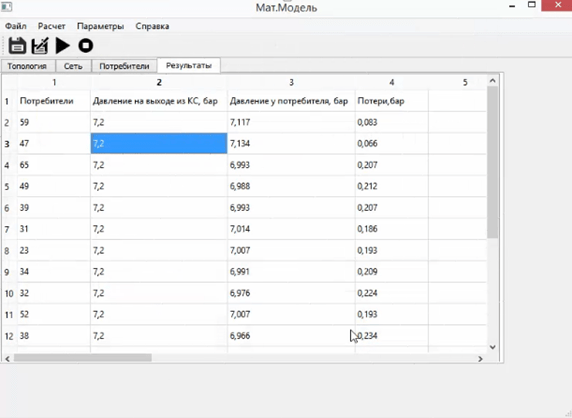

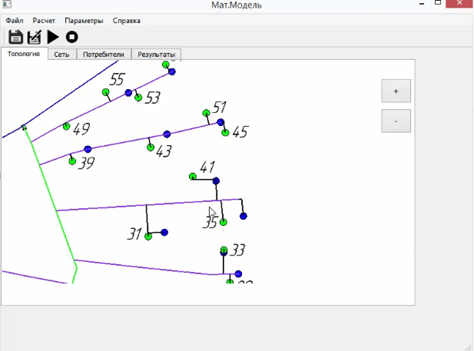

Design and computer modeling of compressors

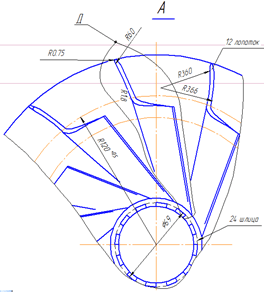

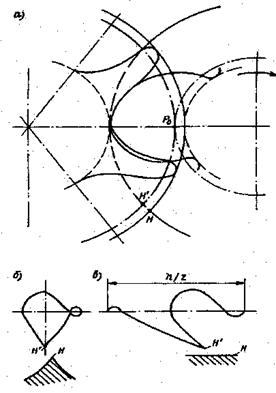

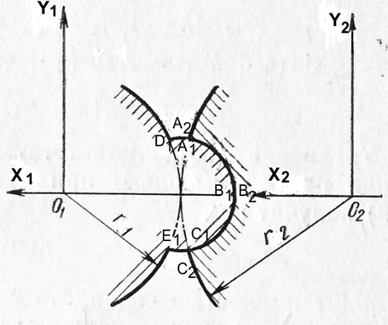

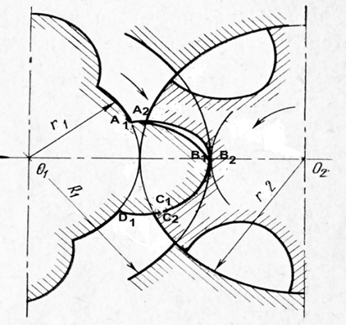

The Department has its own methods of centrifugal compressors flow parts gas-dynamic design, including its own methods of high-efficiency axial impellers design.

According to US rating agencies in 2016, the Department’s research on large-sized ORC of the Central Committee is the world’s leading.

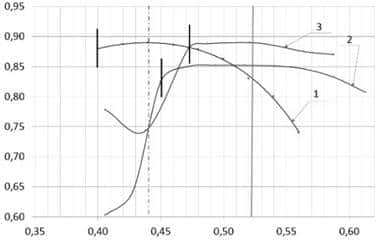

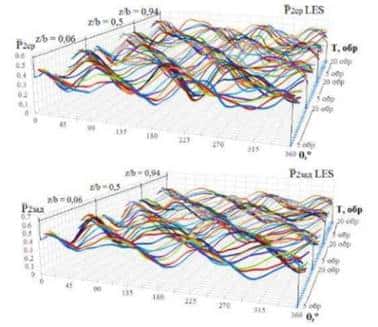

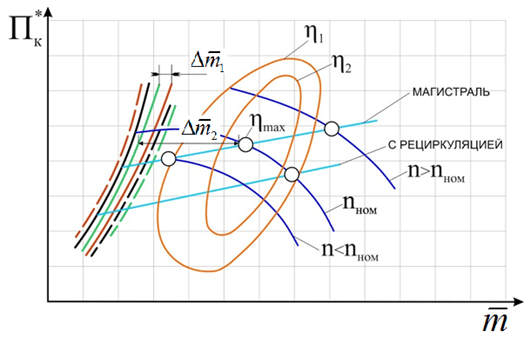

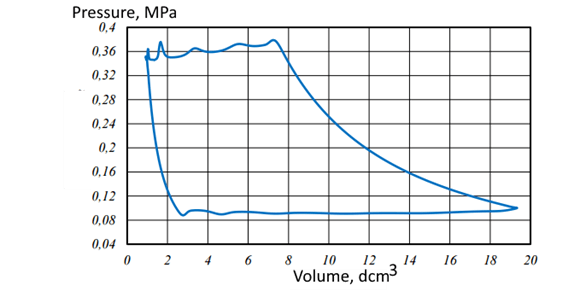

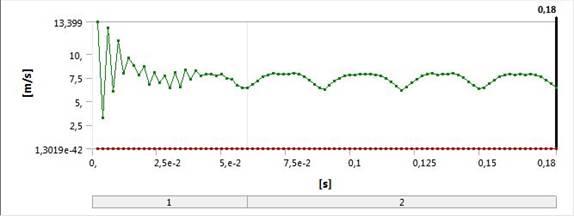

For more than 30 years the Department of “Compressor, vacuum and refrigeration engineering” has been conducting research in the field of non-stationary processes in turbo compressors.

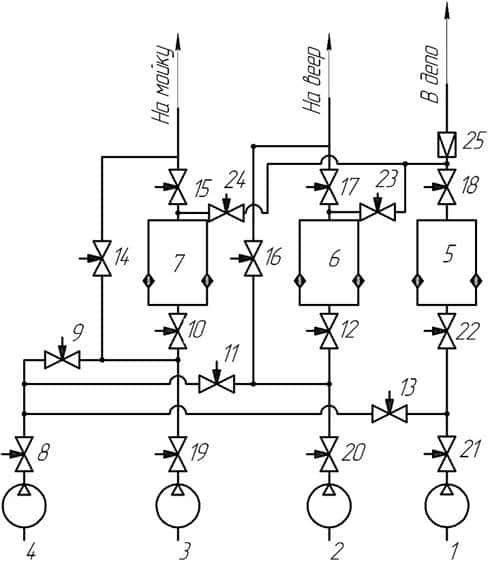

A characteristic system of protection against the turbo compressors surging is being developed.

The advantages of the protection characteristic system against the turbo compressor surging compared with the traditional-parametric are:

- Determination of the reliable surge beginning boundary, regardless of the current operating turbo compressor conditions.

- Expansion of the turbo compressor stable operation zone not less than 5% towards to the surging direction.

- Real-time monitoring of the turbo compressor gas-dynamic stability parameters.

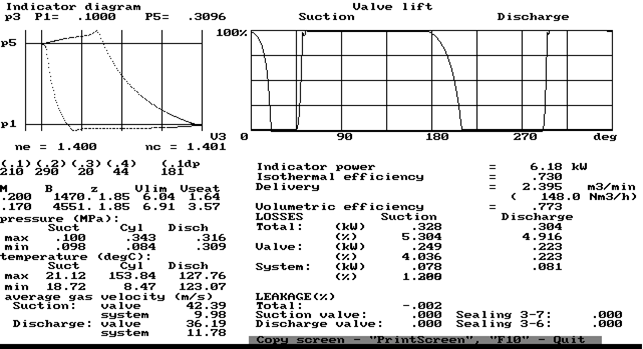

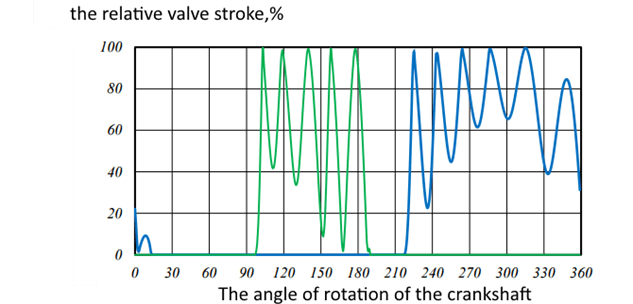

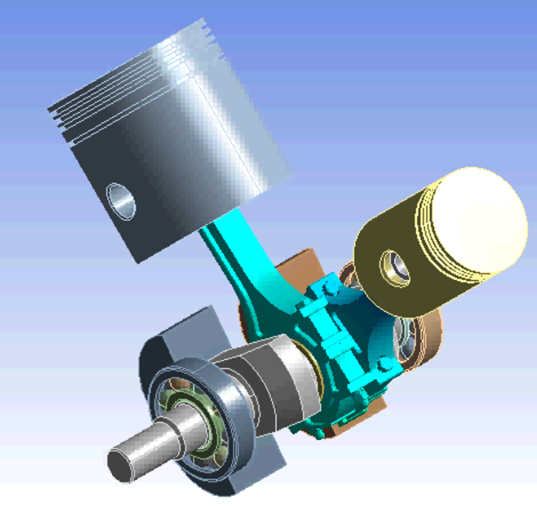

Volumetric compressor

Since 1930 to 2017, 40 phd and 4 doctoral theses about volumetric compressors were defended at the department.