According to statistics, the suboptimal configuration of the pneumatic network, as well as operating modes or compressor equipment types can lead to up to 50% loss of all costs for the pneumatic networks operation.

When considering the pneumatic network operation cost as a whole throughout its life cycle, it is important to consider not only the initial investment in its creation, but also the efficiency of its operation, determined by the configuration and operating modes of the compressor equipment in its composition. These important indicators determine not only the cost of electricity for the network operation, but also the possible increased repairs costs due to suboptimal operation modes. Also, suboptimal selection of equipment at the design stage in the future can lead to additional costs for the purchase of incorrectly selected and often more expensive equipment.

Conducting pneumatic audit will help you to identify existing technical problems of your pneumatic networks and compressor equipment and significantly reduce operating costs!

Specialists of our center have considerable experience in configuration, construction and operation of pneumatic networks and compressor equipment. Conducting pneumatic audit by our forces will help you save up to 50% of all costs for the operation of your pneumatic networks! And since the pneumatic audit can be carried out at the design stage, the savings can be achieved through the purchase of more optimal and often cheaper equipment!

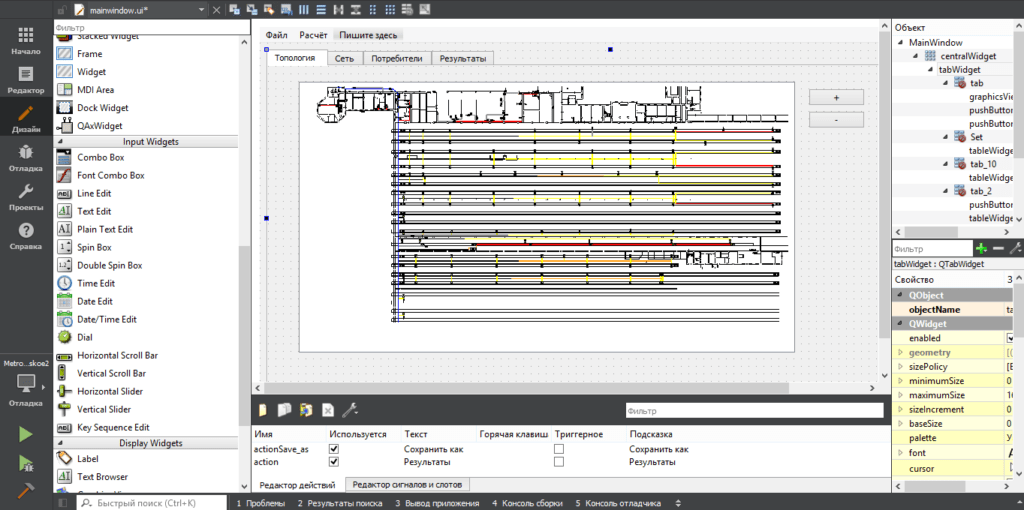

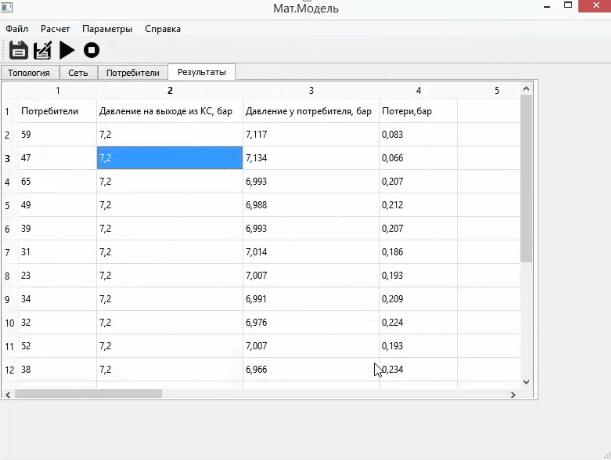

To optimize the networks configuration and compressor equipment operation modes, we use our own specially developed software, the work results quality on which it has been repeatedly tested in the framework of the performed contractual works!

To optimize the configuration of pneumatic networks, based on our practical experience, we have created a program for computer modeling of pneumatic networks operating modes, which allows real-time to see the «bottlenecks» of the customer’s pneumatic networks, and optimize the network configuration to achieve the lowest energy consumption under specified technical and construction constraints.

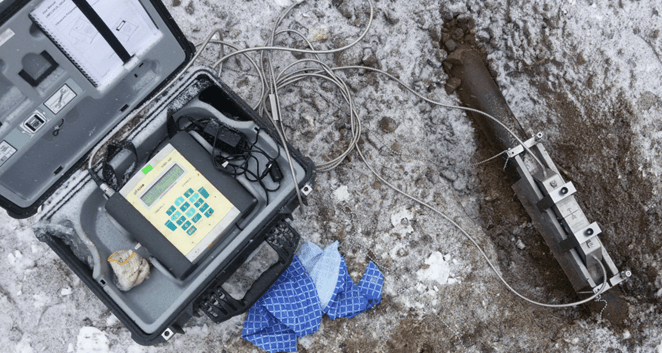

We use the expensive equipment which allows making measurements of compressed air consumption without tie-ins in a pneumatic network and stops of production!

To measure the flow of compressed air in the network, we use an ultrasonic flowmeter Fluxus. It allows you to make measurements without making tie-ins in the network, which require venting pressure from the network. That means, you do not have to stop production!