Dynamic modeling, development of «digital twins» and software

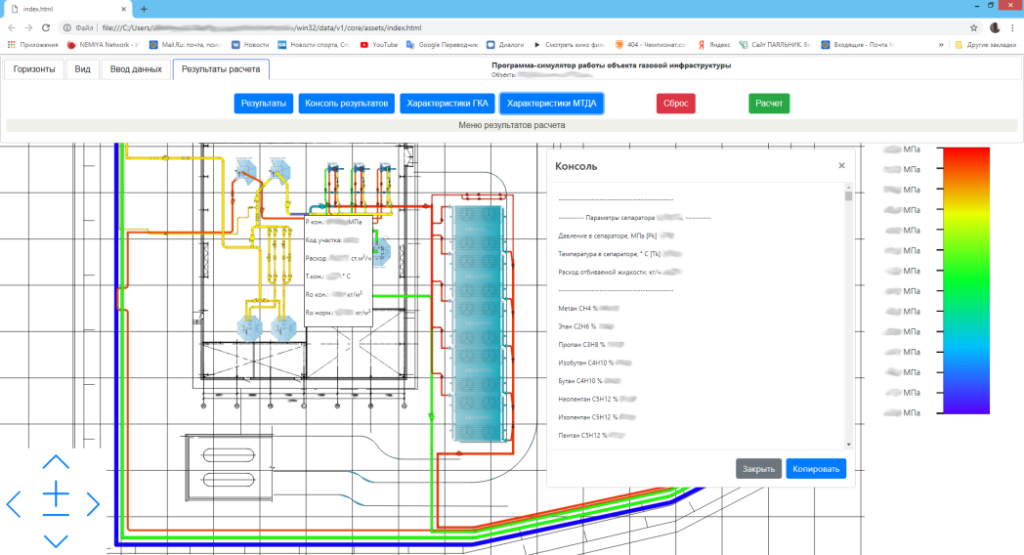

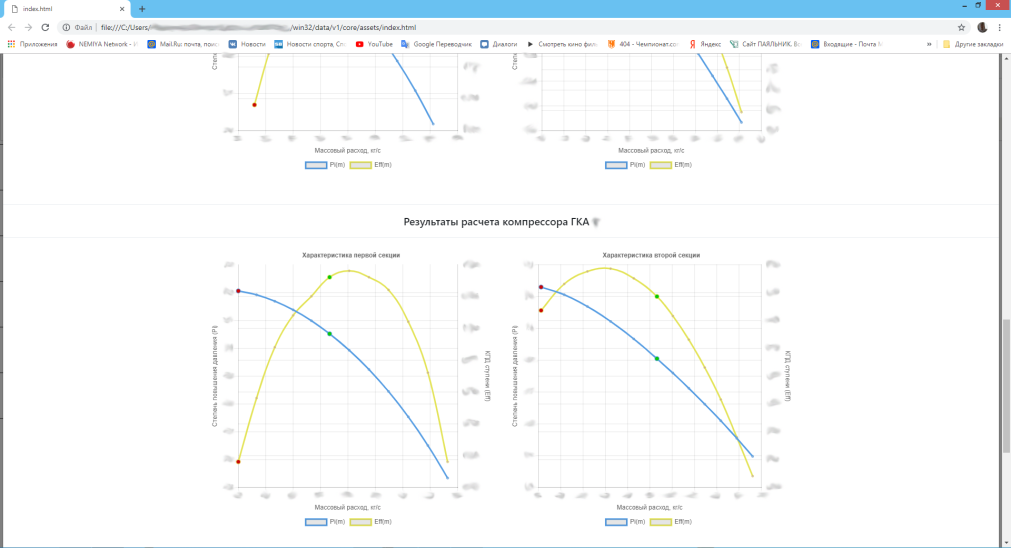

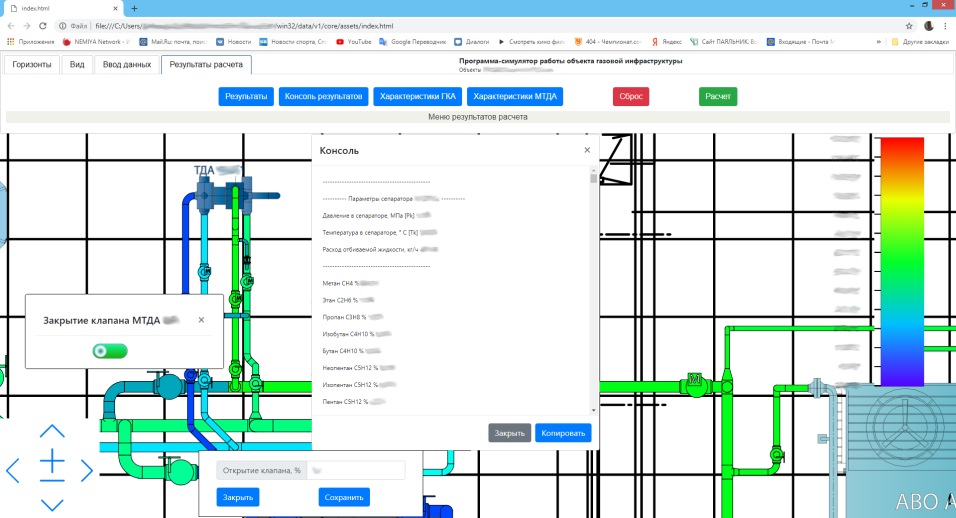

Simulator program “digital twin” of oil and gas objects operational modes complex (it can also be used as a training simulator for employees working at the facility).

The simulator program developed by the specialists of the centre is intended to simulate the stationary modes operation of compression, drying and low temperature separation of petroleum and natural gases.

Changes in external and internal working conditions are taken into account, including various modes of equipment operation, gas composition.

The program allows to simulate the operation of the object for design, current and prospective modes in different seasons. The software product includes mathematical models of system elements complex in digital form (compressors, turbo-expander units, heat exchangers, separators, control valves, dryers, pipelines), combined into a single digital object – digital twin.

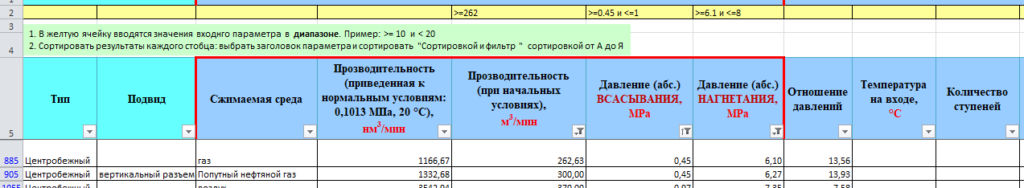

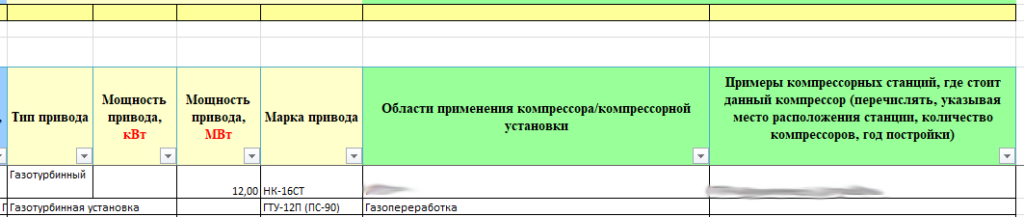

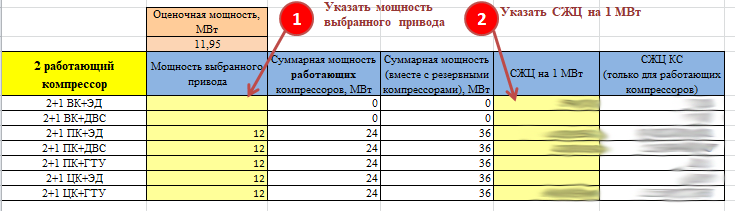

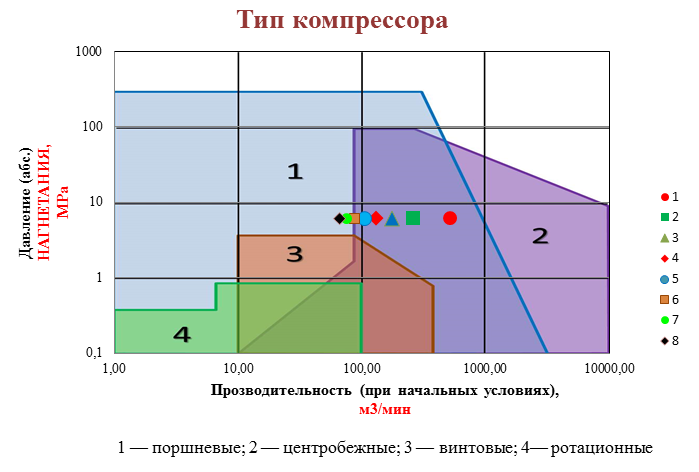

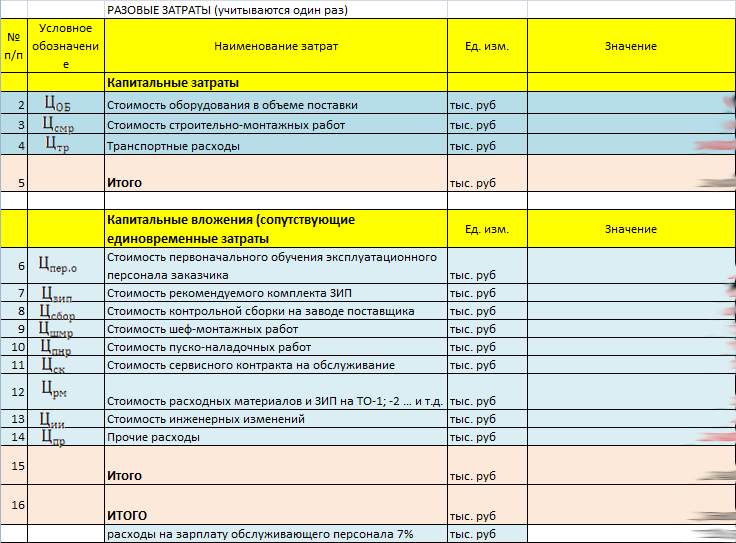

Software product for the selection of compressor equipment (including the drive unit) during the compressor stations design process.

A software product that can be used to select compressors during the design of new compressor stations and existing stations repackaging. The development contains a comprehensive description and compressors and their drives operation principle used in the oil and gas industry, and currently contains more than 2700 operating compressor units. The selecting method of compressor units and gas pumping units is based on the station reliable performance calculation and the life cycle cost. The program is applicable in the preparation of justifications for the compressor units choice in the oil and gas industry and in general industrial facilities. The first version of the software product was developed according to the technical task and with the participation of experts from the PAO “Gazprom neft”.

The program approbation was carried out within the framework of existing industrial facilities. Program versions algorithms are regularly changed for improvement.

Pneumosystem

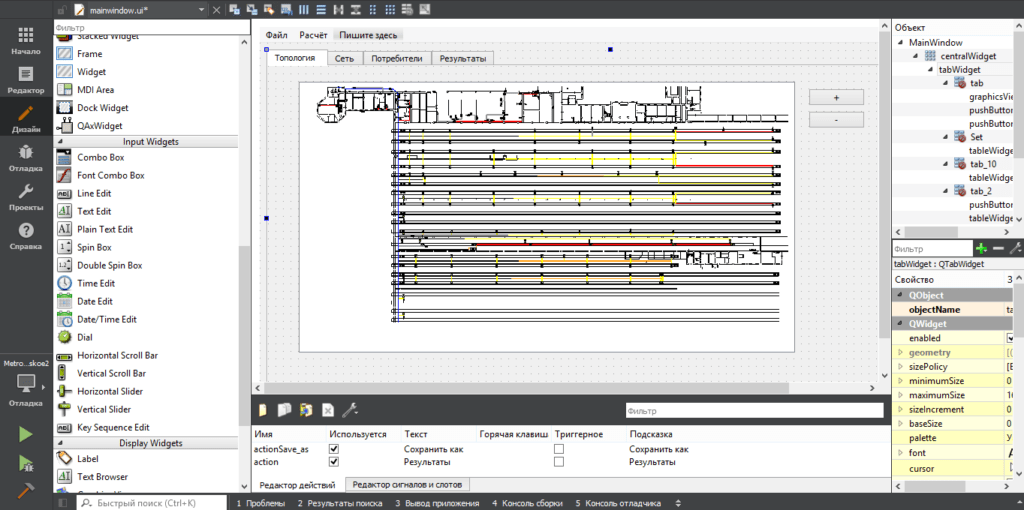

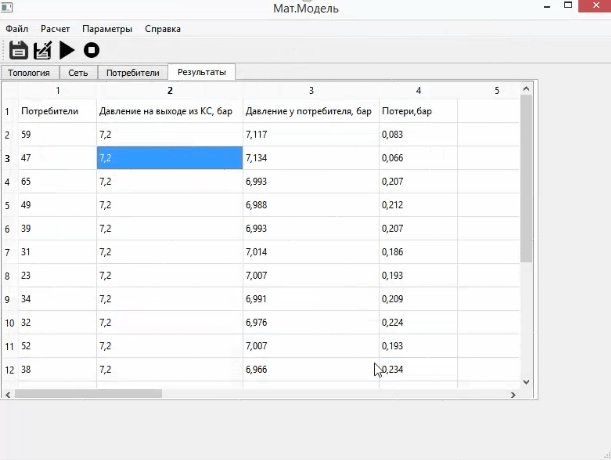

Enterprises pneumatic networks calculation and optimization program.

The program contains a pneumatic system topology compiling module, a pneumatic network mathematical model based on hydrodynamic resistance calculations according to Darcy-Weisbach, as well as Blasius and Nikuradze empirical formulas and Idelchyk loss factors are used. The mathematical model is verified on real objects and contains correction factors that take into account the depreciation of pipelines.

IT IS POSSIBLE TO DEVELOP SOFTWARE SYSTEMS FOR CUSTOMER REQUIREMENTS!

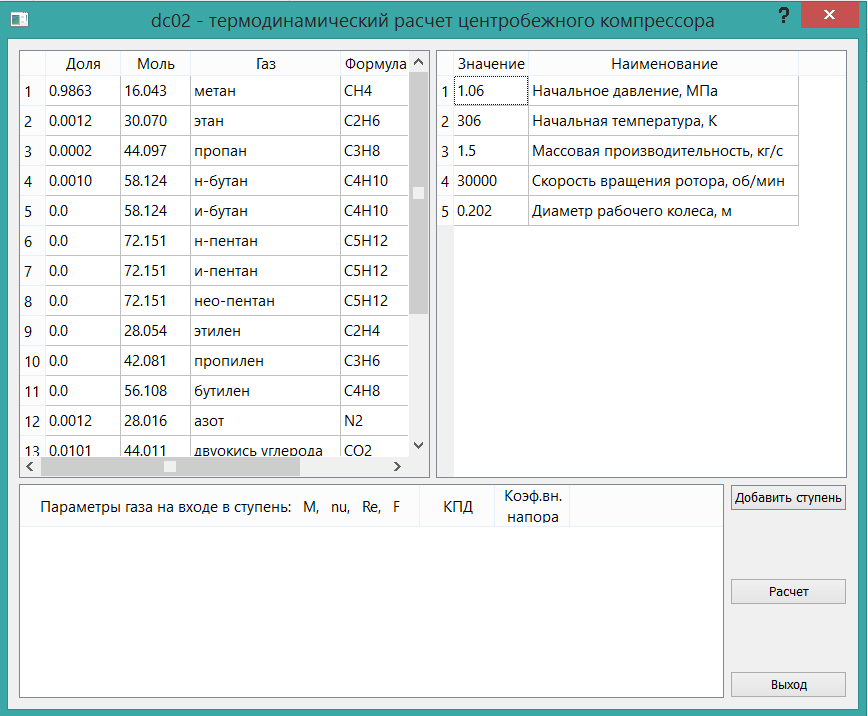

DC02

The thermodynamic calculation program of centrifugal compressors, taking into account the real gas mixtures properties

Unique programs DC00, DC01 and DC02 series is designed to calculate centrifugal compressors taking into account the real gas mixtures properties at high pressures. These techniques are needed in the application in the centrifugal compressors calculation in the oil and gas and chemical industries. Compressor calculation programs take into account the 18 gases properties at high pressures and have no analogues in the world.

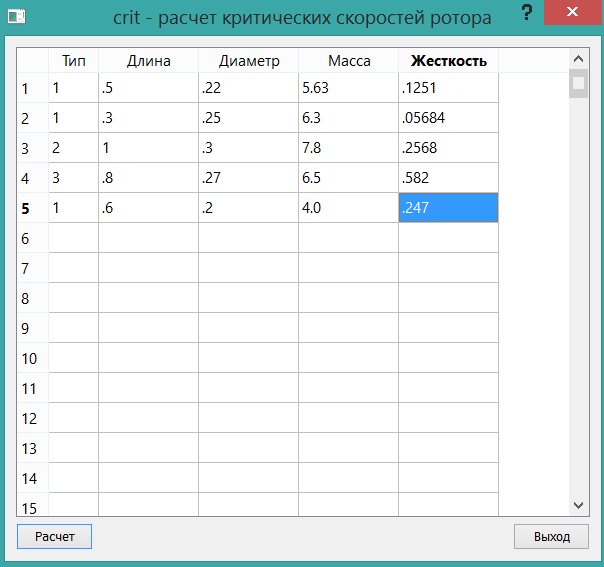

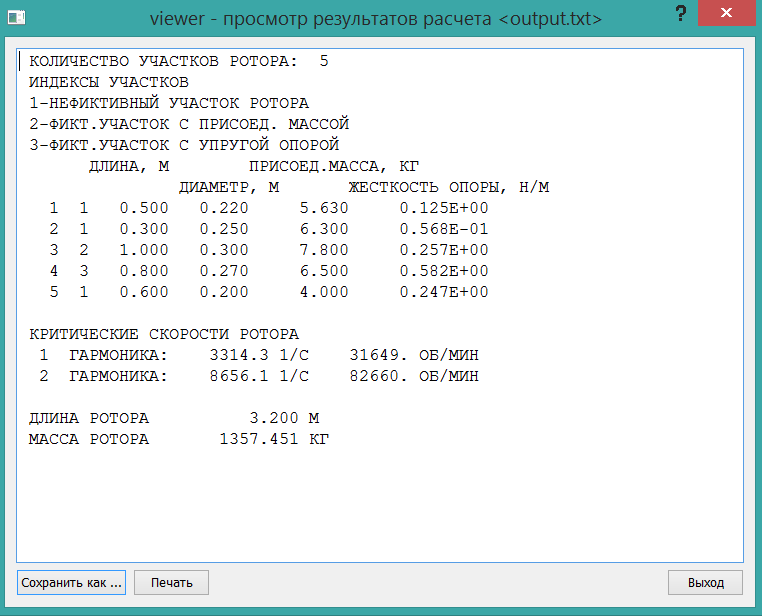

CRIT

The rotors dynamics calculation program

The program is necessary to determine the critical (resonant) rotational frequencies of rotors centrifugal ,axial compressors and any mechanisms. With this program, the material for the manufacture of impellers, selected the rotor configuration. The program is verified on hundreds of real objects. The advantage CRIT over commercial modules for the calculation of rotor dynamics by finite volume methods is speed: multivariate calculations of the rotor configuration for various materials are carried out much faster.

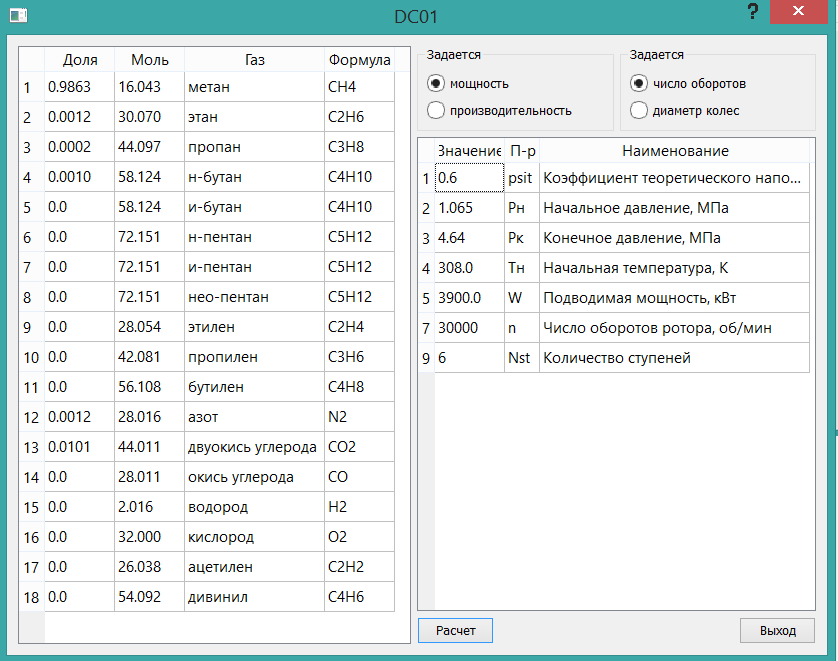

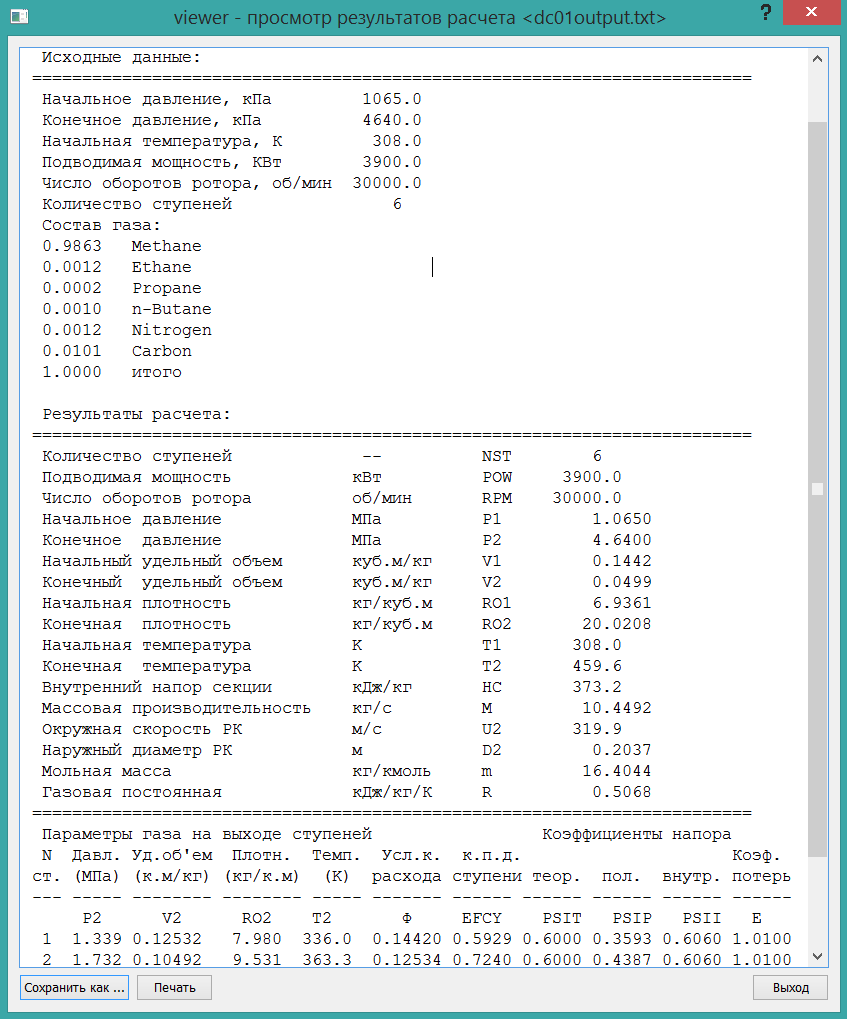

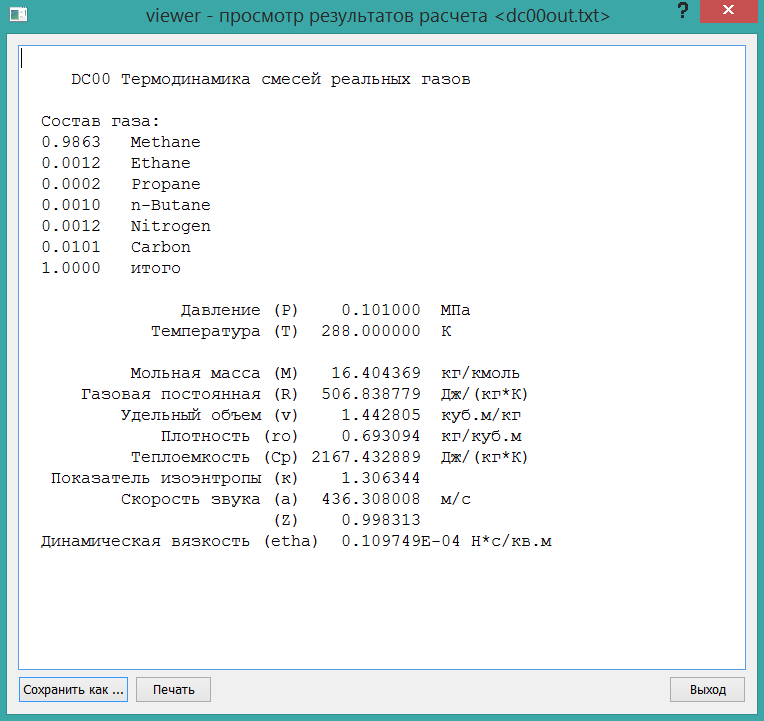

DC01

Thermodynamics mixtures of real gases calculation program

A series of unique programs DC00, DC01 and DC02 is designed to calculate centrifugal compressors taking into account the real properties gas mixtures at high pressures. These techniques are needed in the application in the calculation of centrifugal compressors of oil and gas and chemical industries. Compressor calculation programs take into account the properties of 18 gases at high pressures and have no analogues in the world.

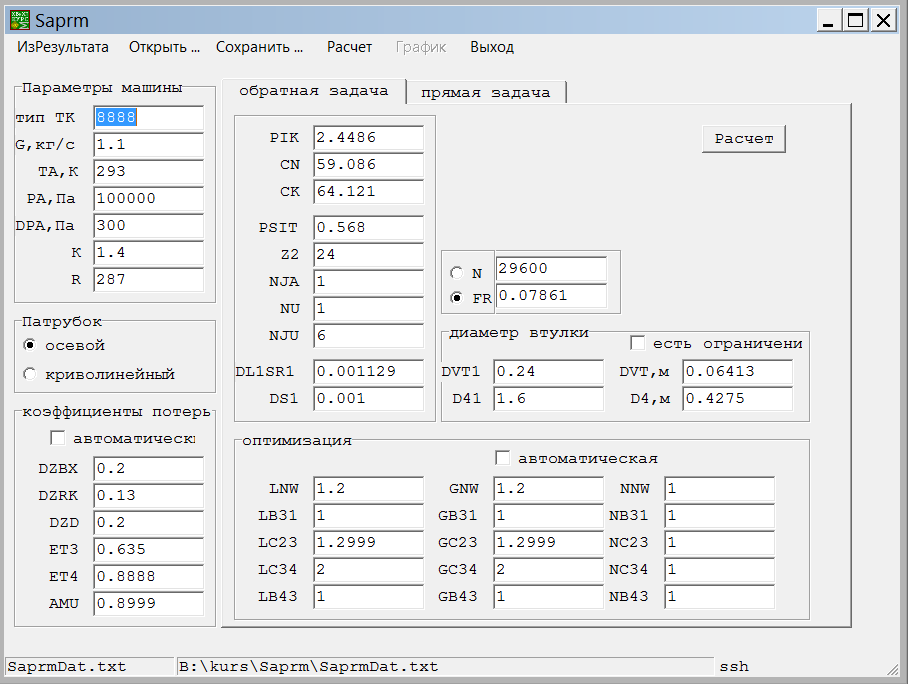

SAPRM

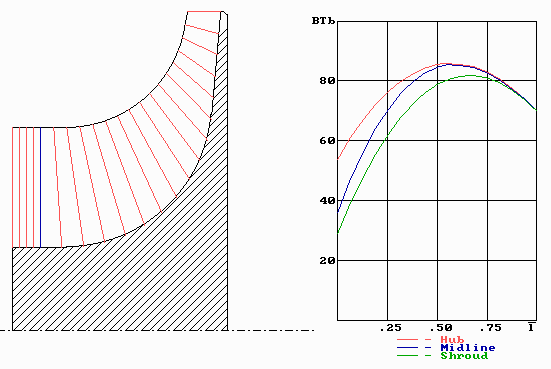

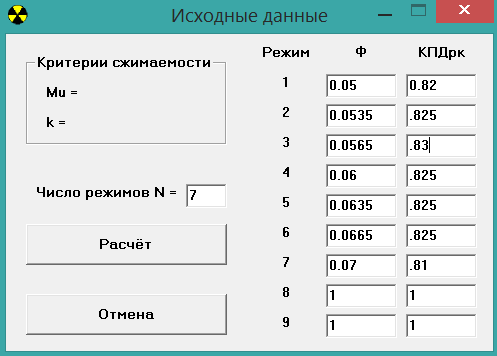

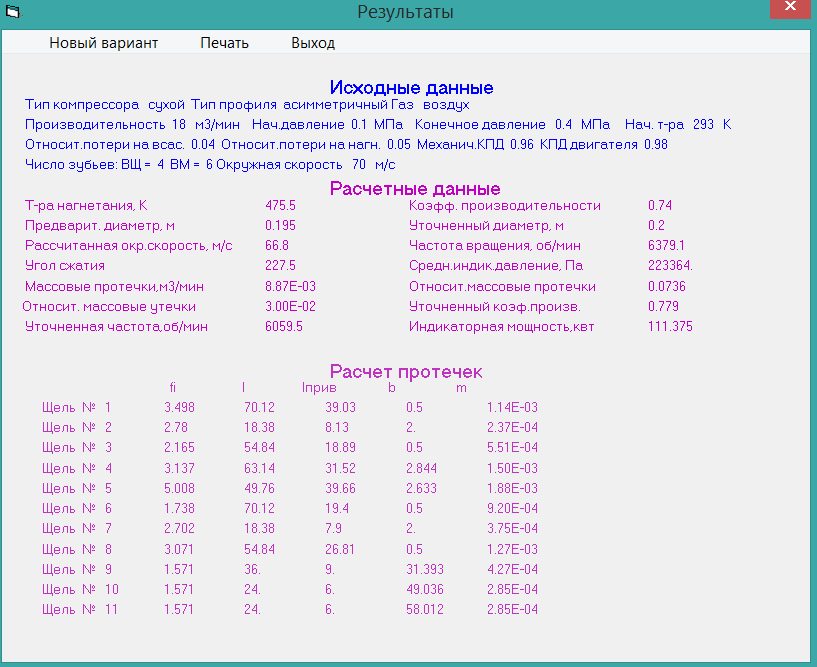

The program for calculating a centrifugal compressor with axial impellers: direct and inverse problems

A special unique program for calculating centrifugal compressors with axial impellers implements developed and verified at the Compressor, Vacuum and Refrigeration Department the calculation methods for the inverse (determining the geometrical parameters of the compressor according to the TOR) and direct (determining the characteristics of the existing compressor project) tasks. The calculation methods implemented in the SAPRM program are recognized as the world’s leading independent US rating agency.

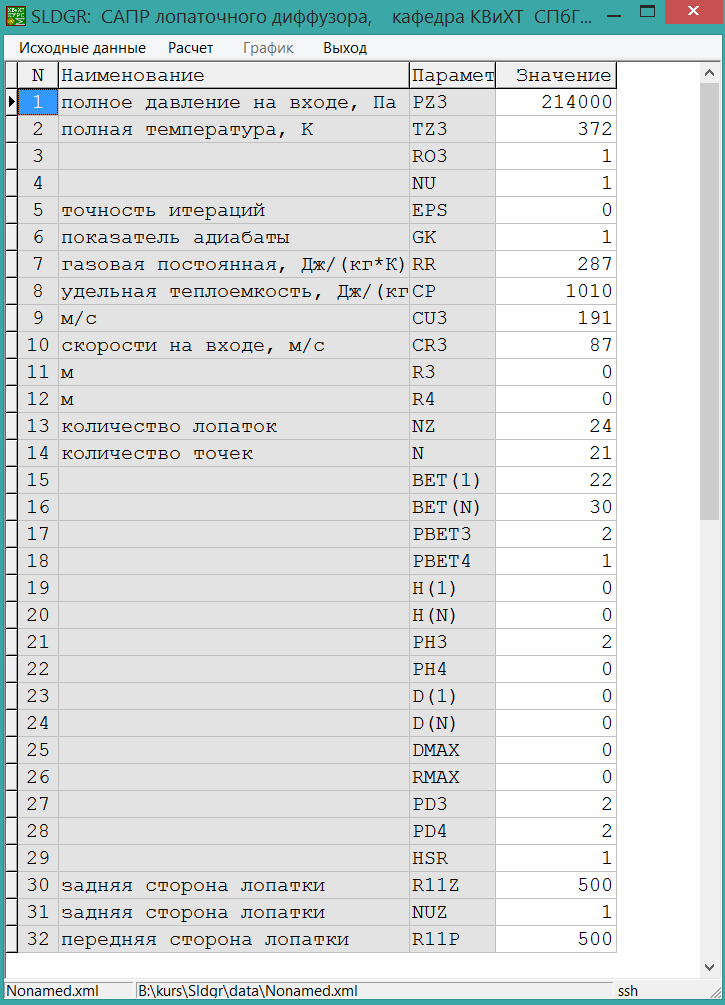

SLDGR

Vane diffusers of centrifugal compressor calculation programm

The program is written using a unique method of optimization calculations for blade diffusers with blade profiling, which was developed at the Compressor, Vacuum and Refrigeration Technique Department and verified on the department stands.

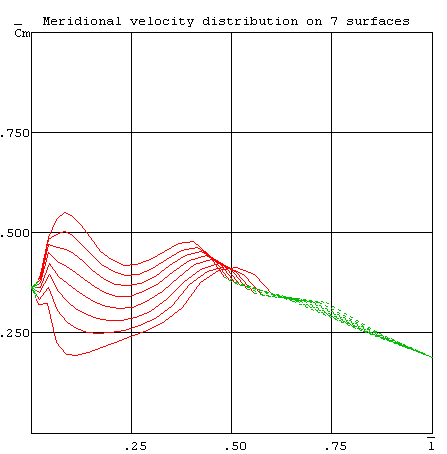

Rask3

The program for calculating the cascade flow of a centrifugal compressor.

The program has implemented a method for calculating the flow around the blades of centrifugal compressors impellers developed at the Compressor, Vacuum and Refrigeration Department, which allows to optimize the average line of the blades to reduce losses during flow.

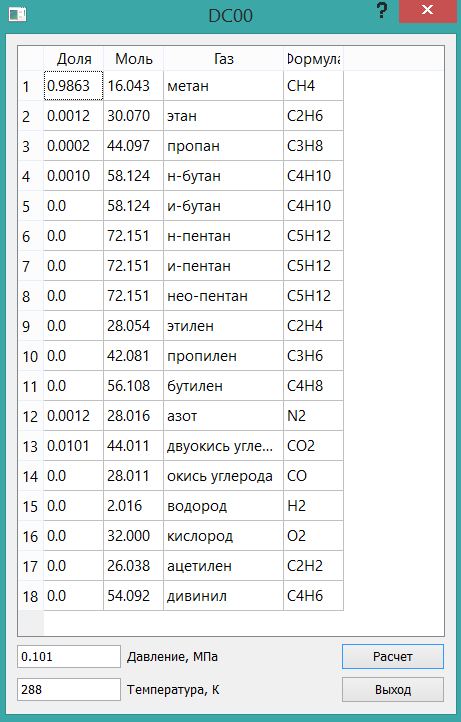

DC00

The thermodynamic calculation program of centrifugal compressors, taking into account the real gas mixtures properties.

Unique programs DC00, DC01 and DC02 series is designed to calculate centrifugal compressors taking into account the real gas mixtures properties at high pressures. These techniques are needed in the application in the centrifugal compressors calculation in the oil and gas and chemical industries. Compressor calculation programs take into account the 18 gases properties at high pressures and have no analogues in the world.

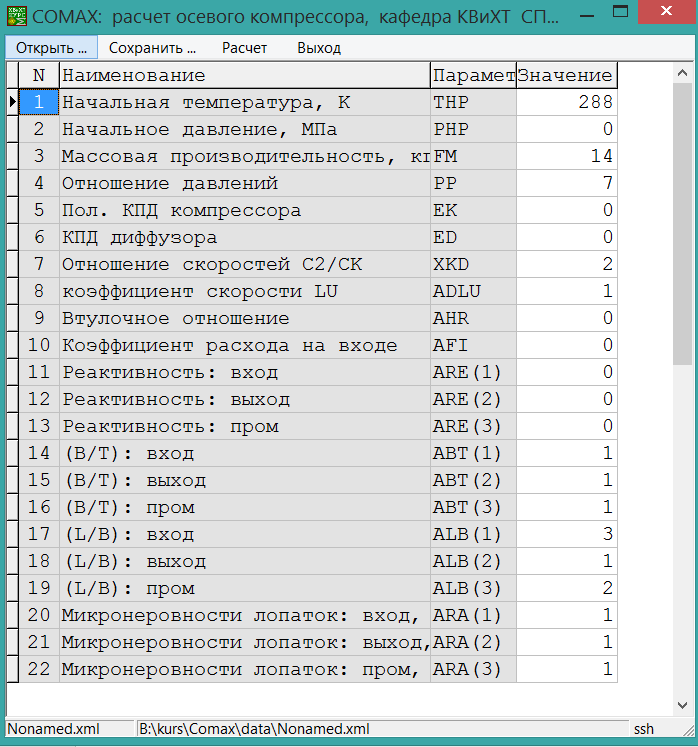

3DM-023

Impeller grate of CC flowing around with non-vicious quasi-three-dimentional flow calculation program

The program has implemented a method for calculating the flow around blades of impellers of centrifugal compressors by an inviscid quasi-three-dimensional flow along the height of the blades. This ensures the optimization of spatial blades of impellers with an optimal determination by the height of the blade angles at the input and output.

MOD-NAP

CC characteristics calculation program

The program allows to obtain preliminary characteristics of the impellers of centrifugal compressors in the whole range of work based on the calculation of a quasi-three-dimensional inviscid flow.

Used for advanced multivariate optimization calculations.

Piston compressor

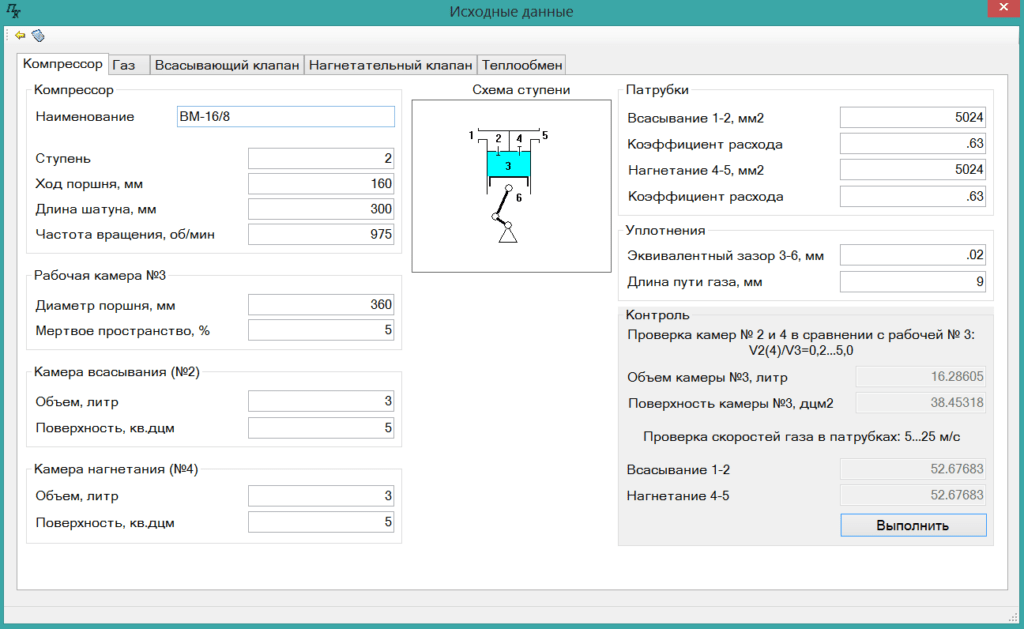

Piston compressor calculation program

The program is intended for the analysis of working processes in a step single-stage piston compressor using mathematical modeling methods. The results contain the following information: indicator diagram, valve movement diagrams, integral characteristics of the stage (power, performance), valve loss, valve opening and closing angles, maximum valve plate speeds.