The history of the “Compressor vacuum, refrigeration engineering and systems of gas transport and processing” scientific and engineering group and “Compressor vacuum and refrigeration engineering” department (years of existence of the department: 1930-2019), Saint-Petersburg Polytechnic University.

2023

From May 24 to 26, 2023, the group held the next annual international industrial conference «Compressor Technologies». The conference once again brought together specialists and managers of leading enterprises, consumers and manufacturers of compressor equipment. Detailed information on the composition of participants and topics of reports can be found on the conference website www.symp.kviht.ru. The next conference «Compressor Technologies» is scheduled to be held from May 22 to May 24, 2024 in St. Petersburg.

During the year, the group’s specialists completed seven works commissioned by industry on the topics of developing new compressor equipment and technologies in the field of gas transportation and processing.

The group’s specialists took part with reports at a number of industry events, including: Conference on the introduction of innovative products at PJSC Gazprom, a session on technological challenges of Gazpromneft-Zapolyarye LLC, educational program «ProGaz 2.0″ PJSC Gazprom-PJSC Gazprom Neft», 4th communication session of partner universities of Gazprom Neft PJSC, and other conferences on refrigeration and compressor topics. Articles have been published in leading Russian and foreign journals.

The first intake of students was successfully completed and on September 1, 2023, study began in the master’s program «Decarbonization Technologies in the Fuel and Energy Complex» of ITMO University, dedicated to the technological, economic and legal aspects of working with greenhouse gases at oil and gas industry facilities, where compressor plants are among the main ones technologies. The initiators and developers of the program were the management of the scientific and engineering group of CVRT&SGTP. The director and leading lecturer of the master’s program is the head of the scientific and engineering group of CVRT&SGTP Yuri Vladimirovich Kozhukhov.

The project manager of the scientific and engineering group, Alexey Mikhailovich Danilishin, successfully defended his dissertation for the degree of Candidate of Technical Sciences on the topic “Increasing the efficiency of turbo-refrigeration machines with end-type centrifugal compressor stages,” scientific advisor Yu.V. Kozhukhov.

The International Academy of Refrigeration (IAR) awarded the head of the scientific and engineering group of KVHT&SGTP Yu.V. Kozhukhov the title of full member, academician of the IAR.

2022

From May 25 to May 27, 2022, the group held the next annual international industrial conference «Compressor Technologies» 2022. This year ITMO University was the General Partner of the Conference — one of the leading universities in Russia, ITMO became the 2022-leader of the main program for the development of universities of the Russian Ministry of Education and Science «Priority 2030». Traditionally, the conference brought together the main consumers and manufacturers of compressor equipment on its site. The participants again noted the high level of the Conference.

The Compressor Technology Conference 2023 will be held in St. Petersburg from May 24 to May 26, 2023. More detailed information can be found on the conference website www.symp.kviht.ru.

Group representatives took part in scientific and industrial conferences and meetings; leaders of the scientific group Yu.V. Kozhukhov and S.V. Kartashov took part with reports in a number of major industry events, such as: «Meeting of the Council of Chief Mechanics of Oil Refineries and Petrochemical Plants in Russia and the CIS countries» 2022, «II communication session of partner universities of Gazprom Neft PJSC», members of the group accepted as invited lecturers participation in courses and training seminars for employees of large oil and gas companies, etc.

New scientific articles and textbooks have been published and prepared for publication. New disciplines for the master’s program have been developed and introduced into the educational process, such as «Automated calculation of the thermophysical and transport properties of natural gas and its main components», «Scientific foundations for the design and operation of pumping and compressor stations», etc.

Master’s and Bachelor’s degree graduates, whose leaders are group members, successfully defended their final qualification theses. The topics of the graduates’ WRC are devoted to advanced methods and designs of compressors, compressor stations, including the problems of operation and diagnostics of equipment for compressing various gases, including real operating facilities.

In 2022, the number of postgraduate students of the scientific group, performing dissertation research on compressor technology, was replenished.

The Group completed and handed over to industrial customers the results of work under five contracts on the topics of developing new models of modern equipment and technologies.

By orders of ITMO University, the head of the scientific and engineering group «Compressor, vacuum, refrigeration equipment and gas transport and processing systems» Yu.V. Kozhukhov was appointed head of the master’s educational programs «Hydrogen Energy» and «Decarbonization Technologies in the Fuel and Energy Complex».

2021

From May 26 to May 28, 2021, the annual international industrial conference «Compressor Technologies» was held. The conference brought together more than 110 participants — managers and specialists from both manufacturers and consumers of compressor equipment. As a result of the conference, a special issue of the journal «Compressor Technologies» was published. More detailed information can be found on the conference website www.symp.kviht.ru.

During the year, the group completed and handed over to industrial customers three major projects. Negotiations are underway on new works with industrial customers.

Published 11 scientific papers, including 5 articles in peer-reviewed Russian and foreign journals (journals of the VAK list, indexed by WoS and SCOPUS), including an article in a journal of the second quartile in the SCOPUS system, a certificate of registration of the Computer Program. Members of the team took part in 4 conferences with speeches, including as an opening plenary report.

Under the scientific guidance of the head of the group Yu.V. Kozhukhov successfully passed the defense of V.M. Ivanov for the degree of candidate of technical sciences on the topic «Improving the quality of numerical modeling and mathematical model of the head of low-flow stages of centrifugal compressors».

In 2021, the group has significantly expanded its area of expertise and ties with enterprises in the real sector of the economy. Work began in the scientific and educational fields with two leading industry universities: the National Mineral and Raw Materials University «Saint Petersburg Mining University» in the direction of mathematical modeling of hydrocarbon transport and the «National Research University ITMO» in the direction of liquefied natural gas.

2020

Due to the epidemiological situation in 2020, the group’s specialists worked mainly remotely.

In 2020, the group’s specialists completed and successfully handed over to industrial customers two projects, including a project carried out in the interests of PJSC Gazprom related to the development of domestic LNG technologies. A grant from Gazprom Neft PJSC was received to carry out work aimed at improving the reliability of gas infrastructure equipment.

Two issues of the Compressor Technologies magazine were issued. You can get acquainted with the issues and subscribe to new issues on the website of the Compressor Technologies magazine www.compressortech.ru.

55 scientific papers were published, including 30 articles in peer-reviewed Russian and foreign journals (journals of the VAK list indexed by WoS and SCOPUS), of which 9 articles were in journals of the VAK list of the Ministry of Education and Science, 21 articles in publications indexed by SCOPUS and WoS, including an article in the journal second quartile, 17 certificates of registration of computer programs, 12 manuals, 8 publications included in the RSCI. Members of the team took part in 4 conferences with the publication of 20 reports.

2019

From May 29 to May 31, the Department of KViHT held the 21st international industrial symposium «Compressors and compressor equipment.» The event was attended by more than 50 companies and 120 people — specialists from manufacturers and consumers of compressor equipment and related services. You can view the report on the symposium here.

About 50 specialists of the companies attended the center’s continuing education courses during the year: East-Siberian Oil Company JSC, TomskNIPIneft OAO, Gazprom 335 LLC, Gazprom Transgaz Surgut LLC, Novatek-Tarkosaleneftegaz LLC, Taneko PJSC , LLC Irkutsk Oil Company, JSC Zarubezhneft, JSC Caspian Pipeline Consortium, LLC Gazprom Neftekhim Salavat, etc.

The group’s specialists commissioned one to industrial customers and accepted two new projects. Two of these projects are related to the priority areas for the development of the fuel and energy complex of the Russian Federation.

Two issues of the journal Compressor Technologies have been released. You can familiarize yourself with the issues and subscribe to new issues on the website of the journal Compressor Technologies www.compressortech.ru.

The group’s specialists took part in reports at 8 scientific and industry conferences in Omsk, Kazan, Moscow, St. Petersburg, Nizhnevartovsk, Novozapolyarny.

The group’s specialists published 8 articles in peer-reviewed publications from the HAC list and 8 articles in publications indexed by the international WoS and Scopus databases.

As part of the university-wide restructuring, the department CVRT was closed along with the rest of the specialized departments of the university (closed from September 1, 2019). The scientific and engineering center «Compressor, vacuum, refrigeration equipment and gas transport and processing systems» operates as usual.

2018

According to the results of 2018 the «Compressor, Vacuum and Refrigeration Engineering” Department became the leader of the «Power Engineering» direction in SPbPU for the third time in a row according to a key financial and economic indicator set by the Ministry of Education and Science.

Advanced training courses were held for the following companies: Sakhalin Energy Investment Company, ООО Gazprom Transgaz St. Petersburg, АО GMS Neftemash, PАО VNIIgazodobycha, PAO Severstal, PAO Gazprom Neft and subsidiaries.

From May 30 to June 1 the 20th anniversary industrial symposium «Compressors and Compressor Equipment» was held by the name of K.P. Selezneva (the symposium former name was “Consumers and manufacturers of compressors and compressor equipment”). The event gathered on its site more than 120 participants — representatives from large industrial companies. The symposium was actively attended by enterprises managers and leading specialists in the field of compressor engineering, service and modernization, as well as companies operating compressors. In total, staff and top managers from 51 companies took part in the symposium events. >>>Report on the symposium can be viewed at this link<<<.

The center’s specialists registered an industry magazine on compressor technology “Compressor Technologies” — Certificate of Roskomnadzor PI No. FS 77-74400 from 11/23/2018., www.compressortech.ru. At the time of its creation, Compressor Technologies magazine is the only specialized edition on compressors and compressor equipment registered in Russia.

As a part of the summer practice, 50 students of the “Compressor, Vacuum and Refrigeration engineering” department had practice in the subsidiaries of PАO Gazprom, PAO Gazprom Neft, PAO Rosneft Oil Company, in PAO MMC Norilsk Nickel, etc.

Students and staff took an active part in XLVII “SPbPU Science Week” — an annual national scientific and practical conference with international participation for students, graduate students and young researchers from Russia, the countries of near and far abroad.

By the order of Peter the Great St.Petersburg Polytechnic University Rector, the «Compressor, Vacuum and Refrigeration engineering» department head Yu.V. Kozhuhov from January 1, 2019 was appointed as the Institute of Energy and Transport Systems Acting Director, of Peter the Great St.Petersburg Polytechnic University (with retaining the post of the «Compressor, Vacuum and Refrigeration engineering» department head).

2017

According to the results of 2017, the «Compressor, vacuum and Refrigeration engineering» department again became the institute leader in terms of a key financial and economic indicator set by the Ministry of Education and Science.

At the request of PAO Gazprom Neft, a regulatory document governing the selection of compressor equipment when designing compressor stations has been completed and submitted for review and approval. A commercial software package for the compressor equipment selection has been developed.

A big two-year contract from OOO RN-Vankor was received..

In the framework of advanced training courses about 130 (one hundred and thirty) employees were trained from such companies as Gazprom, Gazprom Neft, Rosneft, Lukoil, Shell, TGK-1, TANECO, as well as their subsidiaries and branch institutions, by staff of the scientific and engineering center.

45 students of the “Compressor, Vacuum and Refrigeration engineering” department passed summer and winter practices at the largest oil and gas enterprises (also their subsidiaries): PAO Gazprom, PAO Gazprom Neft, PAO Rosneft, and etc. Considering the high qualifications of students in 2017, more than 10 graduates and senior students continued their career as employees of companies where they did internships, including positions at company headquarters.

Another students stream from all over Russia was recruited to the correspondence training of compressor engineers for the oil and gas complex: “Compressors, equipment and oil and gas industry gas transmission networks” and “Compressors, refrigeration engineering and oil and gas industry gas transmission networks”, most of them are employees of industrial companies, 13 people in total.

Cooperation agreements have been signed with Ariel and ООО «Gazprop gazomotornoe topleevo».

According to the order of the university management, the department proceeded to organize the next 20th international symposium «Compressors and Compressor Equipment» named after K.P. Selezneva (the former name » Compressors and compressor equipment consumers-manufacturers»), which was held by the department on the basis of the university since 1994. The symposium was supported by a number of main compressor equipment consumers and manufacturers. The symposium organizing committee membership can be found at WWW.SYMP.KVIHT.RU

2016г.

Acting head of the “Compressor, vacuum and refrigeration engineering” department since 2013 Yu. V. Kozhukhov was elected by the scientific council of Peter the Great SPbPU as a head of the compressor, vacuum and refrigeration engineering department. According to the results of 2016, the department became the leader of the Institute on the key financial and economic indicators set by Ministry of education and science.

A major project for the GUP «Petersburg metro was commissioned (Head of contract V. Kozhukhov, head of work A. M. Danylyshyn).A number of other projects, including the design of a special centrifugal fan for pumping air with acid vapors with bench tests, have been completed. Head of contract Yu. V. Kozhukhov, head of work A. M. Yablokov) development is recognized as a unique offer on the market

A new website WWW.KVIHT.RU a scientific and engineering center of «Compressor, vacuum, refrigeration and pneumatic systems» was launched. For performance of contract works for the real sector economy enterprises the department staff created the center.

A commercial software package for optimization of industrial enterprises pneumatic networks has been developed.

In the direction of compressor equipment and pneumatic networks, three training groups of oil companies specialists were trained

49 students of the CVRE department passed summer practice at the largest oil and gas companies (and their subsidiaries): PAO»Gazprom», PAO «Gazprom Neft», PAO «Rosneft», OOO «Irkutsk oil company», SIBUR, Surgutneftegaz.

30 scientific publications were published, including monographs, textbooks, scientific articles in leading international journals, more than 10 reports have been done at international conferences.

Part-time bachelor’s and master’s programs were opened specifically focused on training compressor engineers for the oil and gas industry: «Compressors, equipment and gas transmission networks of the oil and gas industry» and «Compressors, refrigeration and gas transmission networks of the oil and gas industry.» The first group of part-time students from all over Russia was recruited, most of them are industrial companies employees.

2015

The department is actively strengthening integration into the real sector of the economy. Works on the order of the enterprise were performed. A number of new activities including non-traditional for the department was developed.

Students of the department were trained at ten different enterprises of the oil and gas sector during the summer practice. Enterprises highly appreciated the training of students. Agreements on further development of cooperation were reached. The head of practice was S. V. Kartashov.

The department received 5 new post graduate students, including representatives of leading industrial enterprises. The head is Yu. V. Kozhukhov.

Part-time master degree in the direction of compressor technology was opened. Students are being recruited. The stand for tests of promising centrifugal impellers was started сreation. Preparation for the repair of the department’s premises was carried out.

The department is actively involved in the formation of the supercomputer school technologies at the University and the work of the supercomputer working commissions. Modern computer engineering technologies are being mastered, a number of which have already been successfully tested in the work performed for industrial enterprises.

Three employees of the Department made presentations at the IX international conference on compressors and their systems, which was held from 7 to 9 September in London in City University London. The reports were recognized as corresponding to the highest world scientific and technical level.

A number of new training programmers for industry have been developed.

Employees of the Department published 8 articles in the world’s famous journals indexed in the databases of WoS and Scopus.

2014

The first department website WWW.KVHT.RU was created

By request of the Ministry of Industry and Trade, an analytical report on the assessment of the import substitution potential was carried out by domestic compressor-constructing enterprises (contract manager Y.V. Kozhukhov)

Aerodynamic process of computer modeling the applied scientific researches, strength and deformations, and also dynamics of rotors was expanded.

New software modules for design and optimization of compressor and power equipment have been mastered and implemented in the scientific work of the department.

Two new departmental software products have been developed: calculation of the compressors volumetric actions and calculation and optimization of pneumonetworks.

New educational technologies have been introduced into the educational process and new directions in computer engineering have been opened. Now training in computer engineering in the speciality is conducted from the first semester.

New training programs have been developed and implemented for additional professional education specifically for the modern and future needs of the Russian compressor-constructing and oil and gas industries.

A leading compressor-building enterprises and divisions design departments number of oil and gas companies in Russia and the CIS have repeatedly passed refresher courses at the Department.

5 young graduates of the department were accepted for the professor position, two young assistants were promoted to the associate professors positions, a young doctor of science was accepted as a professor.

The teaching and auxiliary staff of the department also became much younger, with the help of which significant improvements were carried out at the department and adjacent territory.

Repair work was done in the premises and in the courtyard of the department, new furniture was purchased, two new classrooms were opened.

A number of textbooks were published, including “Centrifugal compressor two-tier stage calculation” by Yu.V. Kozhuhov, I.A. Tuchina (St. Petersburg Government Prize for the St. Petersburg universities best allowance), “Dynamic action compressors theory, calculation and design. Test compressors for parallel and sequential operation. Сompressors joint work» N.I. Sadovsky, Yu.V. Kozhukhov, «Stationary axial compressors flow part elements design and calculation » A.V. Zuev, Yu.V. Kozhuhov, V.I. Titensky.

Yu.V. The specialty «Vacuum, compressor technology and pneumatic systems» is the first case of assigning the title in the specialty in accordance with the increased Higher Attestation Commission requirements.

The departments employees joined the industry conferences on compressor engineering, including the topic «Consumers — manufacturers of compressors and compressor equipment.» The department Employees carried out the first masters-compressor issue builders according to the international educational program in English.

2013

Yuri Vladimirovich Kozhukhov was appointed as an acting head of the Department.

In June, the 18th Symposium «Consumers and manufacturers of compressors and compressor equipment» was held.

At the next meeting of ASCOMP the Chairman’s report on the information note was listened that was prepared by him for the member of Council Presidium at the Russian Federation President on modernization of economy A. I. Rudsky about a condition of compressors development and production by the enterprises and the organizations – ASCOMP members on the basis of the information received from them.

November 2013 ASCOMP was one of the organizers and participant of the 11th anniversary forum PCVEXPO Moscow

The textbook «Theory of turbomachines. Fundamentals of the turbochargers theory.” Yu. V. Kozhukhov, Yu. B. Galerkin

2012г.

The 17th symposium «Consumers and producers of compressors and compressor equipment» was held in June.

September

At the LIX scientific and technical session about the problems of gas turbines. CJSC «REP Holding» read the report «The computational gas dynamics methods were used to analyze the efficiency of turbocompressors flow-through parts» Yu.V. Kozhuhov, Yu.B. Galerkin.

October 2012 ASKOMP was a participant of the 11th anniversary forum PCVEXPO Moscow.

November

An extended ASCOMP meeting took place with the question «Public discussion of the work «Low-noise low-vibration compressor stations and special compressor equipment that have a wide range of applications are created and developed in industrial production» submitted for the 2012 Prize that was given by Government of the Russian Federation in science and technology». There were 17 representatives that were invited from enterprises and organizations of St. Petersburg and Moscow.

2011

The 16th symposium «Consumers and producers of compressors and compressor equipment» was held in June.

July 19-20, 2011 The Fifteenth International Scientific and Technical Conference on Compressor Engineering was held in Kazan on the basis of ZAO «NII-turbocompressor named after V.B. Shneppa» and OAO «Kazancompressormash», organized by the Compressors and Pneumatic engineers Association (ASKOMP), ( CJSC NTK), (OJSCKKM), Kazansky (KSTU), (SPbGPU, department CVRE) , (MAX), (AN RT) Tatarstan.

Reports that were heard at the conference:

Head characteristic modeling of centrifugal compressor impeller. Yu. V. Kozhukhov, Yu. B. Galerkin, A. N. Karpov

Non-stationary processes in a centrifugal compressor: from experiment to practice. R.A. Izmailov, A.A. Lebedev

October 2011 ASKOMP was an organizer and participant of the 10th anniversary forum PCVEXPO Moscow.

2010

The 15th symposium «Consumers and producers of compressors and compressor equipment» was held in 9-11 June.

The monograph «Turbocompressors. Methods of gas-dynamic calculation and design» was prepared by the staff of the Department is expected to be out of print.

Six graduates of the Department (a total of eight PhD students) study in postgraduate school.

The centrifugal compressors number, designed by the staff of the Department of CVRE, using the universal modeling method, and working in various industries, reached 300 pcs. (590 types) with a total capacity of 4.5 million KW.

Scientific and technical conference in the framework of the Forum «Pumps. Compressors. Armature» (MVC «Crocus Expo» , Moscow) is dedicated to the anniversaries of the CVRE Department, K.P. Seleznev and the Association of compressors and pneumatic engineers. On the November 25th of this year CVRE Department in conjunction with ASCOMP holds a scientific and technical conference dedicated to the triple anniversary.

2009

The association of compressor and pneumatic engineers took part in the 7th International annual Forum «Pumps. Compressors. Armature» MVC «Crocus Expo». Assistant A.A.Lebedev defended his PhD thesis «Wavelet analysis of non-stationary processes in a centrifugal compressor». A PhD student A. A. Yepifanov defended his master’s thesis «Three-dimensional flow of viscous compressible gas study in the centrifugal compressor impeller using the ANSYS CFX program» and received a grant and an award from the St. Petersburg government for research work.

Associate Professor Yu.V. Kozhukhov is the winner of the Russian Federation President grant competition on the topic «Head characteristics mathematical model of a centrifugal compressor impeller research and development, according to the experimental studies results and non-viscous quasi-three-dimensional flow calculations». Grant number MK-3074.2009.8. Also received a subsidy from the St. Petersburg government to support young scientific and pedagogical staff of St. Petersburg universities.

The department developed sets of documents on academic disciplines according to the State educational standard.

2008

The fourteenth symposium «Consumers-producers of compressors and compressor equipment» was held. The department staff report at the scientific and technical conference in the framework of the seventh annual International Forum «Pumps. Compressors. Armature» (MVC «Crocus Expo», Moscow) was awarded a diploma for introducing scientific research into the compressor engineering practice.

Employees of the department released five textbooks — monographs on the program «Innovative University» and together with the base department «Turbomachine».

First among other SPbSPU departments, the department CVRE carried out the licensing of educational activities.

2007

The 14th SITC (scientific international technical conference) took place in Kazan, Republic of Tatarstan. The thirteenth symposium on «Consumers and manufacturers of compressors and compressor equipment» was held. The Association of Compressors and Pneumatics engineering took part in the 6th International Annual Forum “Pumps. Compressors. Armature» held at the congress and exhibition center «Sokolniki» in Moscow. Nguyen Minh Hai, a graduate of the Vietnamese department, defended his PhD thesis «Informative criteria for the centrifugal compressor presurge condition detection».

Associate Professor Yu.V. Kozhukhov defended his PhD thesis on the “Analysis and Mathematical Modeling of the Centrifugal Compressor Pressure Characteristics Using not viscose Quasi-Three-Dimensional Flow Calculating Results”. He prepared and reads three courses of lectures: “Theory of Turbomachines, Part 1” (this course was awarded the St. Petersburg Government Prize in 2008), “Turbocompressors” — for students from the Department of Compressor, Vacuum and refrigeration engineering. “Energy Machines and plants” — for students of the department “Turbine engines and plants”. Conducts scientific work in mathematical centrifugal compressors flow parts modeling».

At the initiative of company «Nevsky Zavod» the basic department of Power Engineering Faculty was created with the participation the department of «Compressor, Vacuum and refrigeration engineering» and «Turbine engines and plants».

Alexander Nikolaevich Karpov, a student of the department, was awarded a SPbSPU medal for his devotion to science for his excellent study and active participation in STW (Student Research Work).

Masters — graduates the department of «Compressor, Vacuum and refrigeration engineering» A.A. Sofronova, N.S. Lozovaya, D.M. Hamburger were awarded a diploma and a golden medal for their master’s theses in computational gas dynamics by the Russian Federation Academy of Science.

2006

The twelfth symposium on «Consumers and manufacturers of compressors and compressor equipment» was held. The Association of Compressors and Pneumatics engineering took part in the 5th Anniversary International Annual Forum “Pumps. Compressors. Armature» held at the congress and exhibition center «Sokolniki» in Moscow.

Research and defended his PhD thesis on the « Mathematical model of work process in an inlet system with several tanks attached to domestic refrigeration compressors” has been conducted by graduate student from Iraq Vartan Luay. “Compressor, Vacuum and refrigeration engineering” department students D.M. Hamburger, N.S. Lozovaya A.A. Sofronova were awarded with premium and the Russian Federation Academy of Sciences medal for their work “Viscous compressible gas flow analysis in stationary elements of the CC (centrifugal compressor) stage and its optimization using the ANSYS package»

2005

The conference dedicated to the 75th anniversary of the Compressor Engineering Department and the 85th anniversary of K.P. Seleznev birthday was held. The eleventh symposium on «Consumers and manufacturers of compressors and compressor equipment» was held. Employees of the department produced auxiliary materials for the lecture course «Current theoretical and practicing state of centrifugal compressor working process in the gas industry «. The cooperation between our department and ОАО “Turboholod” (Moscow) on the creation of turboexpander units for the gas industry was started. Single-stage centrifugal compressors are designed using the Universal Simulation Method. There will be created about 1 to 3 types of these machines next year.

2004

The 13th SITC (scientific international technical conference) took place in Sumy, Ukraine. For the first time to the beginning of the SITC (scientific international technical conference), the “Conference Proceedings” were published. The tenth anniversary symposium on «Consumers and manufacturers of compressors and compressor equipment» was held. The Association of Compressors and Pneumatics engineering took part in the 3th International Annual Forum “Pumps. Compressors. Armature» held at the congress and exhibition center «Sokolniki» in Moscow. After a significant interruption in the postgraduate study work, L.I. Kozachenko defended his theses on «Clarification to recommendations on the optimal centrifugal compressor stages design based on an experimental study». The manual «Air Cooling

Apparatuses» was released. Two specialists from Indonesia are studying on the programs of 4–5 courses at the department.

2003

Tutorials on the «Methods for calculating, processing of experimental data and designing industrial centrifugal compressors», “Theory, calculation and construction of dynamic action compressors: (compressors testing for parallel and sequential operation), Joint operation of compressors», «Testing a single-stage centrifugal compressor» were released. I. M. Notkina defended her PhD thesis on the “Improving the efficiency of vaneless diffusers low mass flow centrifugal compressor stages based on the analysis of three-dimensional viscous flow». The results of the work were reported to the 5th European Conference on Turbomachinery. Prague, 2003. A.Yu. Prokofiev defended his PhD thesis on the «Improving the centrifugal compressor stages optimal design method by introducing pressure loss model in a quasi-three-dimensional state», T.E. Krutikov defended his PhD thesis on the topic «The system for diagnosing the presurge condition of a centrifugal compressor». The ninth symposium on «Consumers and manufacturers of compressors and compressor equipment» was held. The Association of Compressors and Pneumatics engineering presented their products at the International Annual Forum “Pumps. Compressors. Armature» held at the congress and exhibition center «Sokolniki» in Moscow.

2002

Gas-dynamic calculation and natural gas flow part replacement preliminary design for units GPA-16 DCS «Ural» Yamburg gas condensate field. Gas-dynamic calculations of the compressor GPA-C-16/30-3 ( industrial equipment operation monitoring in name. M. V. Frunze, Ukraine).

ASKOMP is registered as a non-profit organization uniting legal entities.

The methodology of designing and assessing the high-pressure centrifugal compressors reverse guide vanes low mass flow rate stages effectiveness (science team L. Y. Strizhak). The eighth symposium «Compressors and compressor equipment consumers-producers» was held. The international student groups of SPSPU exchange between the Department of KVHT and the Institute of turbomachines TU Lodz (Republic of Poland) was resumed. On the initiative Of the Association of compressors and pneumatics specialists the first annual forum «Pumps, compressors, armature» in which the Department took an active part was organized and held (Sokolniki EC, g. Moscow).

The «viscous» calculations active use for research purposes in collaboration with the high-performance Computing Cluster Technology Center (prof.N. Shabrov) and Educational research and innovation laboratory «Computational mechanics» (Professor A. I. Borovkov) was started. In the period up to 2010 a number of master’s and two сandidate’s theses were completed.

2001

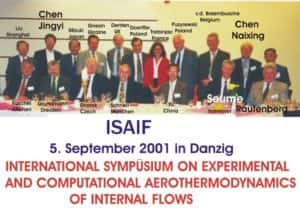

There was XII ISTC (Kazan). The analysis of the SPH booster CBN gas-dynamic parameters increasing by installing blade diffusers was carried out. (CJSC «NIIturbokompressor»). There was natural gas supercharger 48-61-1 «Ural» gas-dynamic parameters testing. (OAO «Compressor complex») Low-flow stage experimental studies at the University of Hanover on DWG-RFBR grant ( l. Strizhak) were completed. The comparison results of the experiment and theoretical calculations by the three-dimensional turbulent viscous compressible flow in a low mass flow rate centrifugal stage with open diffuser stationary elements numerical simulation method based on the complete Navier-Stokes equations for the purpose of geometrical and regime parameters influence on open diffuser work numerical research were reported on the 5th International Symposium on Experimental and Computational Aerothermodynamics of internal Flows.- Gdansk, 2001.Vol.1-P. 255-264. The seventh symposium «Compressors and compressor equipment consumers-producers» was held.

2000

Successful acceptance tests of the 16 MW linear supercharger type 398-21-1 (16 MW, 76 ATM., OAO “Compressor complex”) and a replacement flow part for the superchargers modernization NC-16/76-1.44 (NPO «Iskra»). The projects developed by the staff of the Department showed gas dynamic characteristics above foreign analogues. The machines are accepted for serial production. The sixth Symposium «Consumers-manufacturers of compressors and compressor equipment”. Among the participants, the number of organizations—consumers of compressor equipment has increased dramatically. Nomination by the SPbSTU Council of K. P. Seleznev (posthumously) as part of the authors team for the award of the Russian Federation State prize for work on a new centrifugal compressors generation for the gas industry. Doctoral thesis is defended. The textbook «Calculation of axial compressor blades vibration strength with a large initial twist. Reserve of static and dynamic strength». (Zuev A.V., Strizhak L. Ya.). Four graduates of the Department begin to study in post graduate school.

1999

The first graduation of technical sciences masters took place. The fifth Symposium “Consumers and manufacturers of compressors and compressor equipment” was held. ASCOMP magazine » Compressor equipment and Pneumatics” is published and distributed by subscription every two months. Successful acceptance tests of the the five-stage supercharger 108-51-1 first samples (10mW, 125 ATA, JSC “Compressor complex”) and NC-16 «Ural» (16 MW, 76 ATM., NPO “Iskra”) took place. The projects developed by the staff of the Department showed gas dynamic characteristics above foreign analogues. The machines are accepted for mass production. The first stage of low-flow stage experimental studies at the stand of the Hanover University under the grant of DWG-RFBR (n. gr. L. Ya. Strizhaka).

1998

XI ISTC on compressor construction was held in Kazan (Chairman of the organizing Committee K. P. Seleznev). The Department was named «Department of compressor, vacuum and refrigeration engineering”. The fourth Symposium “Consumers and manufacturers of compressors and compressor equipment” was held. In connection with participation in the program of technical OAO “Gazprom” compressor economy re-equipment big volume of analytical and design developments is executed. By order of the NGO “Iskra” Department staff made the GPA supercharger drive project with a capacity of 16 MW at the outlet pressure 76 bar, by the order of AOOT “Compressor complex”.

1997

The third Symposium “Consumers and manufacturers of compressors and compressor equipment” was held. The first Russian patent of the department (anti-surge protection systems, R. A. Izmailov) was obtained. The staff of the Department began work on the creation of a model stages new generation with vaneless diffusers, resumed intensive experiments at the stand ECC-4, intensive design work on superchargers GPA. Work has begun on the calculation of axial forces, leaks and profiling of the linear supercharger NC-16 «Ural» blade devices (L. Ya. Strizhak, and other employees of the Department). The stages passage parts with axial-radial impellers for power systems GTE ( A. M. Simonov) were developed and transferred to the plant “Kirov-Energomash” (CJSC “Kirov plant”). The programs complex of multistage piston compressors calculation taking into account the reality of gas, heat and mass transfer, dynamics of valves is developed.

1996

The monograph “To the use of numerical methods in the design of the centrifugal compressors flow part” was published. The second Symposium “Consumers-producers of compressors and compressor equipment” was held. On the instructions of AO “Vniiholodmash-holding” and the Ministry of science, the Department staff developed a program of refrigeration CC passages optimal design. A fundamentally new seal design has been developed for high-pressure piston compressors without lubrication or with limited lubrication (V. S. Davydov). The scheme of the hydrogen generator with optimal mass and size parameters (sc. gr. V. F. Zharova).

1995

The work of the scientific conference on compressor engineering (Kazan) was carried out. Admission to the specialty “Vacuum compressor equipment of physical installations” (admission to the Department increased to three groups). The Department has started training of bachelors, engineers and masters. International cooperation is intensifying-participation in conferences in Germany (Hanover, Dresden), Poland), (Lodz, Bronislavov), Japan (Yokohama). Employees of the Department are invited to consult on the new generation of model stages at the dresser Rand plant (Olean, USA). The doctoral dissertation was L. Y. Strizhak “Thermodynamic basis for the design of centrifugal compressors of high and very high pressure” was defended. A software package for optimal design and calculation of GPA superchargers was transferred to NPO Iskra, numerous optimization calculations were performed for AO “Compressor complex” and other organizations. Designs of superchargers passage NC-16/85-1,5 and NC-16/85-1,7 GPA 16MW which are started in production are developed. The method of anti-surge protection was developed with the use of torque stall signals, unsteady processes on a full-scale aviation gas turbine engine TVD-1500 at a circumferential velocity of 640m/s were investigated. R. A. Izmailova). Methods of valves calculation with elastic limiter and disc valve have been developed for piston compressors. The model of one-dimensional unsteady flow of real gas in inlet chambers of piston compressors is developed. The research of the booster piston compressor for mobile AGNKS by the order of OAO “Compressor” (Penza) are executed. According to the volume of contractual works, the Department takes a leading place in SPbSTU.

1994

The first international Symposium “Manufacturers — consumers of compressors and compressor equipment” (180 participants, dozens of organizations from many countries of the world) was organized and held. Cooperation with defense enterprises in the framework of their conversion — AO “Rybinsk motors”, plant “Energomash” AO “Kirovskiy zavod”, NPO “Iskra”. The department is widely involved in the implementation of the PAO «Gazprom» program on modernization and development of compressor facilities (4000 compressors of Gazprom GPA — 20% of all industrial compressors in the world). The method of disks leaks and friction losses calculation in low-flow stages of the CC (sc. gr. L. Y. Strizhak, N. I. Sadovsky). A math model of refrigeration PC was developed, experimental studies of valve dynamics and pressure pulsations were carried out.

1993

The IX (international) scientific and technical conference on compressor manufacturing was held, for the first compressors and Pneumatics time under the auspices Of the Association (Kazan). The curricula for bachelors and masters have been developed. The RSFSR (a new form of state budget funding) higher education Ministry technical program work on six research topics in accordance with the integrated scientific was began. Works on high-speed wind turbine and compressors for agricultural enterprises (n. gr. B. N. Savina). The centrifugal compressors analysis for gas injection into the reservoir, the production of methanol and methanol were done (n of gr. L. Y. Strizhak). The basic provisions of the theory of modeling of working processes in the PC (I. B. Pirumov). A.V. Zuev defended his doctoral dissertation» Fundamentals and optimization of design end seals with floating shaft rings of medium, high and ultrahigh pressure centrifugal compressors”. R. A. Izmailov was invited to lecture at technical University (China). Defense of the doctoral dissertation by A. V. Zuev on the topic » Fundamentals and optimization of design end seals with floating shaft rings of medium, high and ultrahigh pressure centrifugal compressors»

1992

Financing of the problem laboratory has been practically stopped and payment for works under contracts with the industry has been difficult. The number of employees and scientific groups decreased dramatically. With the help of the rectorate, some staff have been transferred to teaching and support positions.

1991

Significantly increased the amount of research on industrial tasks. A number of GPA booster superchargers projects (SMPO named After M. V. Frunze) were executed and transferred to production.

1990

Association of specialists in compressors and Pneumatics (ascomp) began its work , K. P. Seleznev was the initiator of the creation and Chairman. With the help of research Institute «Turbocompressor» stand ECK-8 has been created for the study of high-speed stages of the Centrifugal Compressor. A set of programs for the universal design method has been created for the optimal design of multi-stage centrifugal compressors. Seal Have been Studied the floating ring at a differential pressure up to 1000 M. PA(n. g. A. V. Zuev)The test bench for the study of piston compressors seals has been modernized, and seal tests have been carried out.(NR. I. B. Pirumov)

1989

The eighth scientific and technical conference on compressor engineering was held. The plan was agreed with SMPO and financing of works for all scientific groups on the subject of centrifugal compressors was clarified. The book «Analog methods for studies of flows in Turbomachinery flow part» was published(A. O. Dittmann,K. P. Seleznev,V. A. Serdyukov).Мathematical model of the piston compressor stages with direct-flow valves of the PIK-12 type was developed ( I. B. Pirumova) A complex study of centrifugal compressor stage with the measurement of averaged and instantaneous flow parameters were carried out (L. Y. Strizhak,R. A. Izmailov). In the «NIIT Turbo», «Nevsky Zavod»(supercharger HPA-12) inlets fittings were introduced (V. I. Zykov). Doctoral dissertation was protected by A. M. Simonov, «improvement of aerodynamic calculation methods and optimization stages of centrifugal compressors for General industrial use with high-pressure impellers»

1988

The Branch of the Department at the NPO LenNIIHimmash was organized. The curriculum of the students-researchers group was developed and began to be implemented.

The first award of the LPI Council for the textbook «Reliability and durability of compressor machines» was received.

And the second award for the textbook «Theory and calculation of turbocompressors» was received too. Participation in international conferences in Germany (Essen), Czechoslovakia (CHTU, Prague). Studies performed at the closed circuit stand by the influence of the Reynolds number (n of gr. L. Y. Strizhak). The atlas of model steps was developed (B. N. Savin). The starting system of generators subsplash deep-sea carriers was made. The devices have been successfully tested at a depth of 6000 meters (n. gr. V. F. Zharov).

1987

The manual for “Piston compressors” Universities was released (B. S. fotin, I. B. Pirumov, I. K. Prilutsky, P. I. Plastinin). Interuniversity conference “The use of computers, CAD and ASNI in the training of engineers for refrigeration and compressor machines and installations”was held at the Department. Inlet devices construction LPI has been used in supercharger project.

N-2750 (n. C.V. I. Zykova). Series of turbocharging on tasks units PO “Russian diesel engine” were investigated (n. C. A. M. Simonova, B. N. Savin). On the basis of mathematical model the package of applied programs was created. Calculation of the characteristics of the centrifugal compressor stages was carried out for the first time. The method of thermodynamic calculation was used in the design of superchargers. Employees of the Department participated in the international conferences in Poland and Germany. doctoral dissertation “Unsteady aerodynamic processes in centrifugal compressors”. was protected by R. A. Izmailov.

1986

A textbook for Universities “Theory and calculation of turbocompressors » was released. The recommendations on valves with a gas damper were passed to the “Venibe” plant (n. C. I. K. Prilutsky). The block TAP3T of providing the automated measuring complex with the thermoanemometer (n. gr. R. A. Izmailova). The analysis of CC perspective schemes and designs for gas injection into the reservoir (n. gr. L. Ya. Strizhaka) was done. The experimental stand for investigation of hydrogen and magnesium alloys interaction parameters (n. gr. V. F. Zharova) was made. Development of GOST on terminology and designations in compressor engineering (K. p. Seleznev) was completed together with VNIIkompressormash.

1985

The VII Russian Scientific and Technological Conference of compressor engineering was held at SKB-K in Kazan’ city. Gas-dynamics method of “Centrifugal compressor flowing part” high and super-high pressure calculations for real gases and their mixtures were developed (L.J. Stryzhak). Participation in “CC SVD in VNIIKompressormash” experimental cylinder installation at Sumy city (L.J. Stryzhak). A board hydrogen source for tractor “Kirovets” was made and tested, as well as hydrogen heat generator for underwater conditions (V.F. Zharov). New diagnostics principles of unstable CC modes were developed (R.A. Izmajlov).

Research of compressors with fluid piston on the base of geological exploration well drilling pump were done (A.N. Vejrauh ). Perspective variants of high flow rate stages with dimensional blade form were worked out.

1984

Compressors were developed on V-shaped base PC type 2VUVI-1,5/46 and 2VUVI-3/46, accepted for serial manufacturing on “Armhimmash” Project department (I.K. Prilutsky). Hydrogen generator tests on a microbus in road conditions were conducted (V.F. Zharov). Floating rings were experimentally checked and developed – sealings for pressure up to 70 MPa (A.V. Zuev). Experimental multi shaft CC for general purpose “ECC-30/9 were produced (A.M. Simonov). MM impeller and guiding veins algorithm were developed in quasi-three-dimensional setting. Doctoral thesis “Gas-dynamic, dynamic and strength calculations of self-acting PC valve operation modeling and optimization methods developing” was defended by I.B. Pirumov.

1983

“Heat condition of high-maneuver steam turbines” monograph was published (K.P. Seleznev, A.P. Safonov, A.M. Kovalenko). Sealings — floating rings with an extra supporting surface in a pressure drop to 12 MPa and U2=65 m/s were investigated (A.V. Zuev). ECC-2 stand was upgraded by installing pressure transmitter with switching device. The system of parallel measurement and information processing during experiments about researching non-stationary processes were created (R.A. Izmajlov).

1982

“Centrifugal compressors” monograph was published. Unified centrifugal stages were developed and atlas was published. Devices for gas-liquid mixtures compressing in geological exploration drilling were tested (A.N. Vejrauh ). Series of contact-labyrinth seals PC in pressure 35 MPa were tested (V.S. Davydov). Hydrogen generator and unit on the car UAZ-452V were constructed and produced as well as road tests were made (V.F. Zharov). Seven PhD theses were defended, including two scientists from Cuba (V.I. Zykov).

1981

The VI Russian Scientific and Technological Conference of compressor engineering was conducted (LPI branch in Pskov city). FP superchargers GPA-C-6,3 with low layer pressure modifications were researched. The development of the FP GPA-C-16 for 12MPa has started. Research of low consumptions stages and CC project developments with pressure till 250 MPa for large tonnage technological lines of polyethylene and others were started (L.J. Stryzhak). Stand for researching shaft sealings with pressure till 108 MPa was set in exploitation (A.V. Zuev). Ending axial-centrifugal section for axial-centrifugal blast-furnace compressor K-6400 was developed. Mathematical models of sealings for PC with disk and differential pistons were developed. RGA of low-consumption centrifugal stages research were finished (L.J. Stryzhak).

1980

Closed outline stand for research and work out of super-high pressure CC stages was set in exploitation. Turbocompressor design for experimental line “Polimir-145” was started in collaboration with LenNIIhimmash. Works of creation unified PC row for general purpose, which superior the best abroad analogues in technico-economic indicators, were done in collaboration with VNIIKompressormash. Experimental research of sealing shaft floating rings dynamics with pressure up to 12MPa were conducted for the first time. Method of calculating and profiling of high-flow axis-radial impeller was developed. On the base of vicious flow calculation parameters in FP.

1979

The course “Experiment theory and technique” (R. A. Izmailov). The Department Achievements were demonstrated at VDNH and awarded with diplomas and medals. Unified centrifugal stages for SKB-K-KKZ compressors have been developed and submitted for implementation. The mathematical model of the increased informativeness piston compressor is developed and practically tested. A series of studies on the noise of centrifugal compressors is completed (sc. gr C. A. M. Simonov). For the first time in the USSR, a method for calculating the 3 dimentional compressible flow in the inlet champers of turbocompressors and a method for their optimization (sc. gr. V. N. Zykova). A new design of ultrahigh pressure plunger of piston compressors for polyethylene is proposed and implemented. The technique of ideal fluid flow electromagnetic modeling in the system «blade diffuser + snail»(sc. gr. S. A. Anisimova).

1978

V conference on compressor engineering (MVTU, Moscow) was held. The Scientific Council on the problems of compressor and pump engineering was organized under the chairmanship of Prof. K. P. Seleznev. In accordance with the Resolution of the SCNT №. 242, a number of single-stage centrifugal superchargers of general purpose (S. A. Anisimov, A. M. Simonov, V. A. Sherstyukov) have been developed. The study of noise and ways to reduce it in high-pressure centrifugal compressor stages with axial impellers (n. gr. A. M. Simonov) was done. The complex of works on creation of high-efficiency and reliable strip valves with elastic limiters is finished. Valves are commercially available (for compressors VU-2,5-5,0/12) and individually for a whole range of general and special purpose compressors. Work has begun on hydrogen generators and hydrogen engines (together with the department of internal combustion engines). A contract was signed with the Havana Polytechnic Institute. H. A. Echeverria on improving the educational process and research at the department of thermal energy.

1977

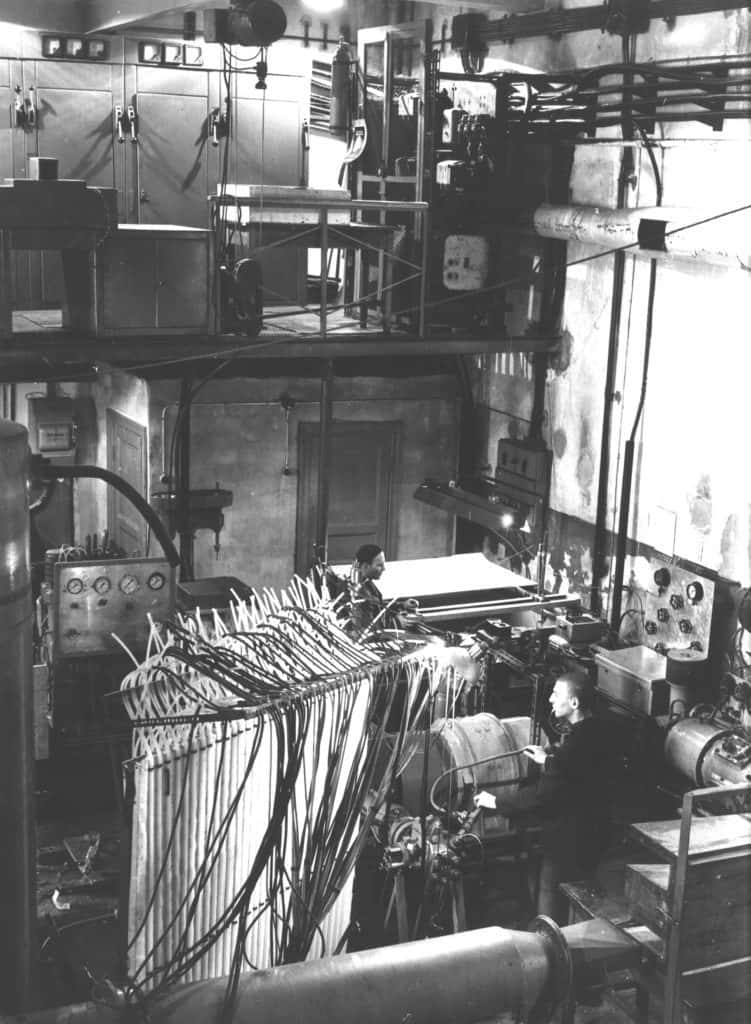

A box for piston and centrifugal compressors stands was built. Student design bureau has released a sample of the microcar «Minicar» commissioned by the “Kirov plant”. The cycle of centrifugal compressors intermediate stage studies with variable geometry of the flow part was completed, which allowed to expand the working area of the characteristics almost by 2 times (n. gr. V. I. Zykova).

1976

A course of lectures » Reliability and durability of compressors» was delivered. The department is involved in the work of SCNT. The volume of research reached 500,000 rubles. per year. An automated information-measuring system for the study of non-stationary processes in centrifugal compressors (n. gr. R. A. Izmailova) was created. A method for calculating the characteristics of the centrifugal stage is developed. The complex of works on target application of mathematical modeling at optimization of again projected piston compressors design and their separate knots (VM-24/12 Krasnodar compressor plant, VU-1,52,5/12 on Armkhimmash) is completed. The results of the the highly efficient vortex microcompression study (V. I. Fantalov) were received and transferred to industry. Together with Lenniihimmash and VNIIkompressormash for the first time in the USSR the project of the the ultrahigh pressure turbocharger pilot cylinder (L. Ya. Strizhak) is developed. B. S. Fotin defended his doctoral thesis » piston compressors working processes».

1975

A collection of programs for the new curriculum has been released. On the basis of the study of stages with axial impellers, the original project of a low-consumption centrifugal compressor at =30 m3/min and =9 was developed (A. M. Simonov). A student design bureau was created for the development of microcars and hydrogen engines (head V. F. Zharov). The LPI technique for profiling spatial high-flow centrifugal impellers with high efficiency was experimentally tested. The study of one — and two-tier blade diffusers with different blade profiles (V. I. Khentalov, V. A. Sherstyukov, V. V. Rossel) has been completed. The technique of high-pressure blade diffusers profiling is developed taking into account the state of the boundary layer on the blades (n. gr. A. M. Simonov). Work began on the creation of high-speed, pressurized piston compressors for general industrial purposes. Studies of seals with floating rings at pressures up to 9.8 MPa were carried out.

1974

The 4th All-Russian scientific and technical conference was held in VNIIComressoromash in the town Sumy.

“Positive displacement compressor theory” (B.S. Fotin, I.B. Pirumov) and “specialization introduction” courses were established. Self-acting valve with flexible arrester and valve calculation method with plate movement multi-mass tasking were developed. Rapidly rotating shaft seal research with pressure below 32 MPa were started (A.B. Zuev). Electro-magnetic modelling method of ideal gas flow in impeller and blade diffuser was developed and implemented practically (S.A. Anisimov, V.I. Hentalov, V.A. Sherstukov). Doctoral thesis “Centrifugal compressor impeller flow research” was written by S.N. Shkarbul. Experimental piston compressor with frequency 3000 s/min was developed.