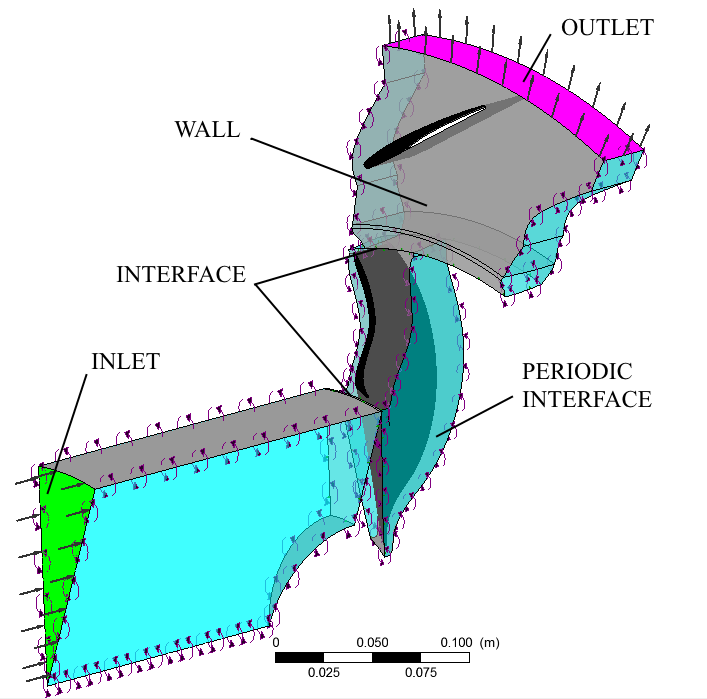

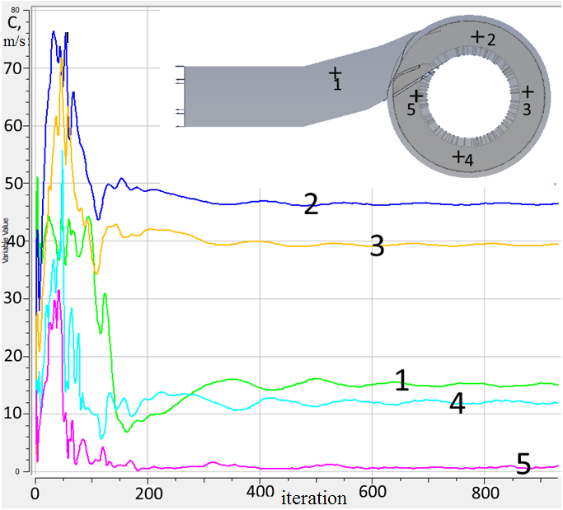

Abstract. The study presents the results of multi-objective optimization for a high flow centrifugal compressor stage with impeller pressure ratio П=1.3 and conditional flow rate coefficient Φ=0.108. The compressor stage includes an impeller with 3D backswept blades, a vane diffuser and an axial inlet. The goal of optimization is to increase polytropic efficiency and polytropic head ratio of the basic design. The CFD method is used to estimate compressor efficiency at rated duty. CAE optimization is applied based on the parametric optimization of impeller shroud contour and number of blades of the impeller and diffuser versus the original design. Parameterization of geometrics is also used to the width-ratio of vane diffuser in the range of b3/D2= 0.08-0.097. The study considers 52 cases of the optimization of impeller shroud contour and the number of blades in the search for the improved design. The optimization procedure uses the automatic generated computation grid and supplementary activation of solution to each design case. The numerical calculation for each case has been performed automatically by ANSYS CFX 14.5 soft application. The optimization allowed to obtain the improved design with total polytropic efficiency increase by 1.58% for the impeller and polytropic head coefficient increase by 0.58%. The polytropic efficiency and the polytropic head coefficient are calculated on the total parameters. The performance of the basic impeller has been exhaustibly validated by test records provided JSC “REPH ZAO”. The resulted error range does not exceed 5% over the performance map, except near surge point.

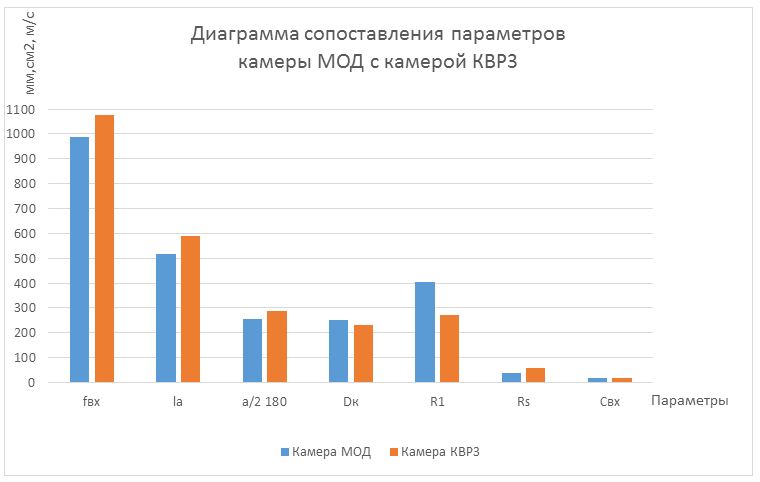

Abstract. The purpose of this work is to determine the optimal configuration of a flowing part of the plenum chamber of the centrifugal compressor of natural gas based on numerical experiment. In the research process was the analysis of the gas-dynamic perfection of a flowing part of the compressor plenum chamber, carried out the calculations to determine the parameters and effectiveness of the plenum chamber by methods of computational fluid dynamics. The result of the work revealed the shortcomings of the original design and determine the expected performance and efficiency optimized plenum chamber.

Выпускные квалификационные работы студентов кафедры КВиХТ 2019

From May 29 to May 31, 2019 Peter the Great St. Petersburg Polytechnic University had been hosting the annual 21-st Industrial Symposium “Compressors and their equipment” by the name of K.P. Seleznev conducted by the Department of Compressor, Vacuum and Refrigeration Engineering of the Institute of Energy and Transport Systems.

СОВЕРШЕНСТВОВАНИЕ МЕТОДИКИ ПРОЕКТИРОВАНИЯ ВХОДНЫХ РАДИАЛЬНЫХ КАМЕР ТУРБОКОМПРЕССОРОВ

Гилева Л.В.1, Кожухов Ю.В. 1, Зуев А.В.1

Компрессорные машины широко используются в нефтегазовом машиностроении. Экономичность компрессорных машин характеризуется коэффициентом полезного действия. По литературным данным адиабатический к.п.д. ступени центробежных компрессорных машин: не превышает 0,75 — 0,85 для стационарных машин и 0,60-0,80 для транспортных компрессоров. Адиабатический к.п.д. ступени осевого компрессора — 0,84-0,92. К.п.д. компрессорной установки при отсутствии охлаждения имеет, соответственно, меньший уровень.

ARE THERE ANY QUESTIONS LEFT?

Call us: +7 (812) 715-41-64

or leave the request and get the advice from our expert